New Tennessee FRP bridge to promote composites use for rural infrastructure

Embedded fiber-optic sensors to give IACMI and industry partners critical performance and safety data of composite bridge deck, promote federal, state and local adoption of composites.

All photo credit: IACMI

Developed by Structural Composites Inc. (SCI, Melbourne, Fla., U.S.), a newly installed composite bridge in north central Tennessee is said to showcase sustainable solutions for aging infrastructure. Equipped with a fiber-reinforced polymer (FRP) bridge deck embedded with fiber-optic sensors, it has replaced a damaged, decades-old concrete crossing which, like thousands of rural, low-volume bridges across the state and nation, was rated structurally deficient and outdated. Working together under the umbrella of the Institute for Advanced Composites Manufacturing Innovation (IACMI, Knoxville, Tenn., U.S.), almost a dozen private companies led by Tennessee-based Composite Applications Group (CAG, McDonald) partnered with industry organizations and university researchers to make the composite bridge a reality.

According to the American Society of Civil Engineers (Reston, Virg., U.S.), about 8% of the more than 617,000 bridges in the U.S. are structurally deficient and need repair. FRP composites offer a low-cost, low-maintenance option and the new structure in rural Tennessee and is intended to demonstrate the benefits of composite materials for rural bridge work.

“This composite bridge has already made a positive impact on Morgan County,” says Morgan County Highway Superintendent Joe Miller, who added county officials were looking for a low-maintenance bridge that could be installed fast and at a lower cost than traditional methods. “We have numerous bridges within the county and hundreds across the state that are in need of repair and could benefit from this technology.”

FRP bridge fabrication.

The 16 x 25-foot bridge deck is engineered for high strength and is said to be 90% lighter than concrete. It has two 8 x 25-foot corrosion-resistant FRP deck panels that were fabricated off-site in a controlled environment. Because the completed bridge sections were so lightweight, they could be transported to the bridge site and installed in one day using a forklift, reducing installation time and energy costs by requiring less construction equipment for on-site preparation.

IACMI Technology Manager John Unser, who is also vice president of program and project management for CAG, says composites have been used for bridge deck applications for more than 20 years and have exceeded all performance and safety standards set by the American Association of State Highway and Transportation Officials (AASHTO, Washington, D.C., U.S.). But when it comes to composite bridge decking, he says, many transportation departments across the country, especially those from smaller jurisdictions, are not familiar with the technology.

IACMI and its industry partners are developing a comprehensive case study based on the Morgan County bridge project, including comparing total costs of a typical concrete bridge and one using an FRP bridge deck. Unser says the results will be shared with federal, state and local officials, transportation departments and the civil engineering community so FRP composites will be more a “known” to them.

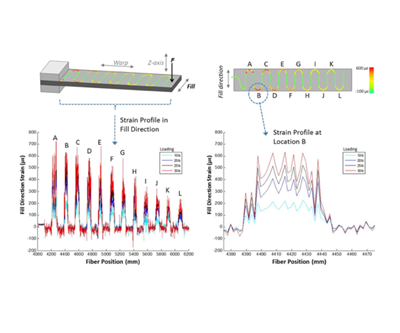

University of Tennessee, Knoxville (UTK) researchers and engineering students from the Fibers and Composites Manufacturing Facility are part of the bridge partnership. They embedded smart fiber optic sensors developed by Luna Innovations (Roanoke, Virg., U.S.) into the bridge surface during production. These high-density sensors are being used to monitor the composite deck system over time to give critical performance and safety data, thus providing a sustainable solution for aging infrastructures such as bridges. In addition, wireless technology developed at UT is being used for monitoring the response of the bridge system and traffic counts remotely via cloud computing.

“Lack of durability data is one of the major barriers of the adoption of novel and advance materials including carbon-, basalt- or glass fiber-reinforced polymeric composites in civil infrastructure,” says Dayakar Penumadu, the Fred N. Peebles Professor in the Tickle College of Engineering at UT and Characterization Fellow for Materials and Processing for IACMI.

Penumadu adds, “this is a major obstacle for integrating new materials and structures quickly and thus require successful demonstration as being done through this IACMI project. Bridge decks are the most damage prone elements, and we are integrating smart sensors distributed throughout the composite bridge deck that will provide us valuable performance data with time for years to come.”

Related Content

CCG meets customer demand with StormStrong utility pole lineup

Additional diameters build on the portfolio of resilient FRP pole structures for distribution and light pole customers.

Read MoreSwedish parking garage to incorporate decommissioned wind blades

Architect Jonas Lloyd is working with Vattenfall to design the multistory building with a wind blade façade, targeting eco-friendly buildings and creative ways to remove blades from landfills.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreSGL Carbon carbon fiber enables German road bridge milestone

A 64-meter road bridge installed with carbon fiber reinforcement is said to feature a first in modern European bridge construction, in addition to reducing construction costs and CO2 emissions.

Read MoreRead Next

Fiber-optic sensors shed light on the toughest composite design challenges

Designers of composites are learning that if they are to be able to guarantee component and system performance, repeatability and reliability, it is critical that they have access to more sensor and test data.

Read MoreComposite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More