Notus Composites celebrates manufacturing milestone

The company has produced the one millionth square meter of its glass fiber-reinforced prepreg, for use in Dubai’s Museum of the Future.

Dubai Museum of the Future. Source | Notus Composites

Notus Composites (Ras Al Khaimah, UAE) has announced a manufacturing milestone with its one millionth square meter of fire retardant (FR) epoxy prepreg shipped from its UAE facility this month for use in the composite Museum of the Future in Dubai. Including the museum Notus says it is supplying FR materials for several high-profile infrastructure projects in the Middle East.

The one million square meter milestone was reached during a recent production run of Notus’ EPFR-609 glass fiber-reinforced epoxy prepreg, which the company says is a user-friendly FR prepreg with a long out life that is designed for low pressure/vacuum curing at temperatures from 85-120˚C. EPFR-609 can also be supplied as a resin film or as Notus N1-Preg, the company’s versatile single-sided prepreg product format.

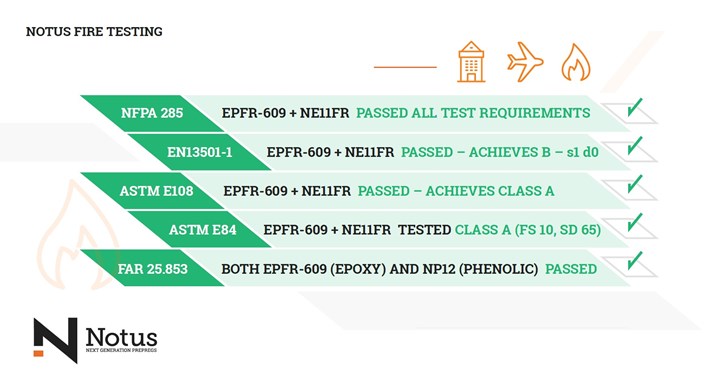

Since its start as a company in 2015, Notus Composites has completed an extensive program of testing at well-known fire research laboratories in the Middle East and Europe, focusing on large-scale tests to verify material behavior as part of a complete wall or façade system.

Source | Notus Composites

Notus Composites says its EPFR-609 prepreg and NE11-FR surface film is the only epoxy prepreg system to have passed the NFPA 285 exterior and curtain wall test and to have achieved an impressive B2,s1,d0 rating when testing to the European EN13501-1 standard. These materials have also been approved by the UAE’s Dubai Civil Defense, one of the Middle East’s leaders in building fire safety coding.

“It is a fantastic achievement to reach 1,000,000 square meter of FR prepreg,” says Mihir Shah, managing director of Notus Composites. “We’ve come such a long way since 2015 and are now supplying into some of the largest and most complex composite construction projects in the Middle East. It’s great to see our investment in testing and development being successful, as our clients continue to deliver ever larger FR composite structures.”

Related Content

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

.jpg;width=70;height=70;mode=crop)