NRL’s robot predicts how composites will perform in large aircraft

As private companies and the military continue to look to advanced composites for new aerospace and other applications, NRL's robot may help get aircraft from factory to fleet faster.

The U.S. Naval Research Laboratory (NRL) has built a robot to pull, bend and twist samples of the composite materials used to build F/A-18s and other aircraft, according to a new report from the NRL.

The F/A-18 Hornet became the U.S. Navy and Marine Corps' first strike fighter in 1978 and the median age of today's active aircraft is 22-23 years old. As F/A-18s continue to age beyond their design life cycle, showing structural stress corrosion cracking and wing panel composite skin abnormalities, engineers have had to do extensive analysis to develop repairs. This is where the need to certify a new material comes in.

Today, the Department of Defense (DoD) uses a "building-block approach" from 1999, as set out in the Composite Materials Handbook-MIL 17. The approach starts with testing fibers and matrix materials. However, the tests get, as the handbook states, "increasingly more complicated," until reaching the level of structural subcomponent (or higher).

"I can tell you that qualifying the system for the F/A-18 took about 13,000 specimens and about 18 years,” said John Michopoulos, group leader of the NRL project. "Engineers are forced to conduct tests at multiple scales because they do not really have a theory to connect the behavior across multiple scales."

As private companies and the military continue to look to advanced composites for new aerospace and other applications, NRL's robot could help get aircraft from factory to fleet faster.

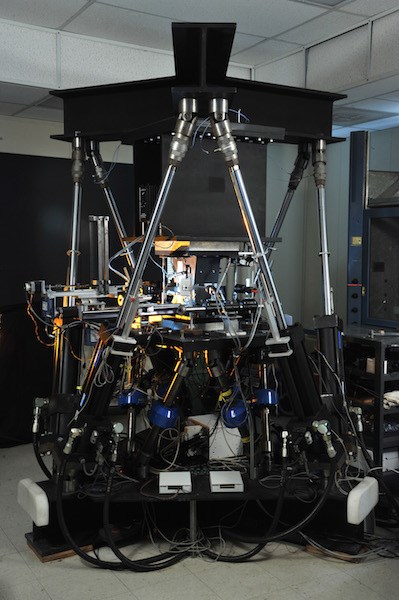

Named NRL66.3, the robot is a "multiaxial loading machine." It has six devices that apply linear movement, termed actuators, in a hexapod configuration. While a material sample is held by a fixed grip from one end, the actuators move a grip that holds the other end of a material sample, moving it in any combination of up to three translations and three rotations. So the robot can "apply combinations of tension or compression, bending, and torque simultaneously," Michopoulos said.

The NRL66.3 is fully automated. Assisted by two other robots, it will take 72 specimens of the material used in part of an F/A-18, and apply 72 loading paths in that six-dimensional space. The robot loads each specimen until it snaps, then quickly moves onto the next. A custom-developed machine vision system, with four cameras, captures digital images of what's happening in real-time.

While the experiment is going on, the scientists use custom-developed full field measurement algorithms Michopoulos' group has now patented to "take those digital images and analyze them, and convert them to displacement and strain fields."

What the experiments do is to, very quickly, capture what might happen to an advanced composite in the real world. Advanced composites age in a very particular way. "The resin that's between the fibers starts developing little micro-cracks," says Michopoulos, which can cause the resin to separate from the fibers or the fibers to break. "A continuous accumulation of micro-cracking (that leads to a softening of the material) can be used as a metric for material degradation assessment."

The group has, over the past 20 years, used various robots to test more than 150 different material systems, with potential applications for ballistic missiles to rocketry to automobile manufacturing.

Related Content

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More