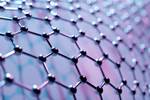

OCSiAl to construct European graphene nanotube facility in 2024

Synthesized graphene nanotubes and other nanotube derivatives at new hub in Serbia will meet customer demand for high-performance EV batteries, polymers.

Graphene nanotubes manufacturer OCSiAl (Luxembourg) has been granted a construction permit for a nanotube production facility near Belgrade, Serbia. The nanotube synthesis plant will be launched in 2024 and will have an initial annual capacity of 60 tonnes. Over the next two years, the capacity of this plant will be increased to 120 tonnes per year.

“The project will facilitate logistics and lower supply chain costs. European-produced nanotubes and nanotube derivatives will be primarily supplied to our customers in central and western Europe, North America and Asia,” OCSiAl Group senior vice president Gregory Gurevich says.

In addition to synthesizing nanotubes, the facility will manufacture nanotube suspensions for lithium-ion battery manufacturers in Europe, the U.S. and Asia — enough to enhance the performance of more than one million electric cars with an average battery capacity of 75 kilowatt-hours per car. According to the company, its nanotubes create long and robust electrical networks between active material particles, improving key battery characteristics, including cycle life, lower DCR, C-rate performance and cohesion between active battery material particles, making the battery electrodes more durable. Graphene nanotubes unlock new battery technologies, including high-silicon content anodes, thick LFP cathodes, fast-charging graphite anodes and more. They can be applied in conventional and emerging battery tech, such as a dry battery electrode coating process, and solid-state batteries.

The OCSiAl facility will also involve manufacturing of nanotube concentrates for high-performance polymers. The project, supported by the Serbian municipal and national governments, has passed environmental impact assessment and is 100% powered by green energy. The plant is planned to be certified in accordance with ISO 9001, ISO 14001 and ISO 45001, and to be compliant with the IATF 16949 automotive industry standard. The project will create more than 200 job opportunities for engineers, scientists, managers, operators and administrative staff.

Currently, OCSiAl has an extensive manufacturing system of nanotube-based products in regions with high market demand, such as China, Japan, Sri Lanka, Brazil, Malaysia and other countries. The Serbia nanotube hub will operate in conjunction with the company’s operational R&D center and planned graphene nanotube synthesis facility in Luxembourg — together, they will significantly strengthen the stability of OCSiAl’s supply chain and increase the cost-efficiency of nanotube technologies for its customers.

Related Content

-

Seat frame demonstrates next-generation autocomposites design

Light weight, simplified/cost-effective manufacturing, passenger comfort and safety informed materials and process innovations and won awards for the 2022 Toyota Tundra‘s second-row seat frame.

-

Composites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

-

SABIC launches fiber-reinforced, intumescent, fire-retardant resins

SABIC PP compound H1090 and Stamax 30YH611 resins are well suited for extruding and thermoforming large, complex EV battery pack components for automotive.