Orion spacecraft successfully completes major testing

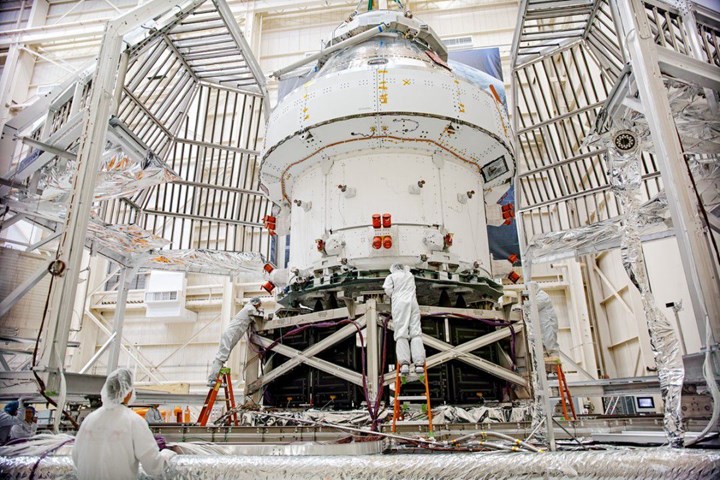

In preparation for the Artemis I mission, NASA’s Orion spacecraft has recently completed systems-level testing in a simulated space environment.

Source | Airbus

Update: NASA Administrator Jim Bridenstine announced on March 19 that as part of NASA’s emergency response to the coronavirus outbreak, further production and testing for Orion hardware will be temporarily suspended.

Airbus announced on March 16 that the Orion spacecraft for NASA’s Artemis I mission has successfully completed several months of simulated space environment system-level testing in the NASA-owned thermal vacuum chamber at Plum Brook Station in Ohio, U.S. The tests were conducted in two phases: a 47-day thermal vacuum test and a 14-day electromagnetic compatibility and interference test in ambient conditions, which both simulate the conditions the spacecraft will encounter during its voyage to the moon and back to Earth.

The results of this test, according to the engineering teams from Airbus, the European Space Agency (ESA), Lockheed Martin (manufacturer of the spacecraft) and NASA, prove that the spacecraft is suitable to navigate safely through the extreme conditions that it will experience in space.

“...We proved to our customers ESA and NASA that the European Service Module, designed and built by our engineers in Bremen – supported by companies in 10 European countries – meets the requirements to withstand the harsh conditions in space,” says Andreas Hammer, head of space exploration at Airbus.

Orion will be transported back to the Kennedy Space Center in Florida to undergo further testing and prepare the spacecraft for integration with the Space Launch System rocket.

ESA’s European Service Module, which was built by Airbus under an ESA contract, will provide propulsion, power, air and water for the astronauts, as well as thermal control of the entire spacecraft. Artemis I will travel around the moon and back to Earth. Airbus’ Bremen, Germany location is already building the second Orion Service Module for Artemis II, where astronauts will fly to the moon and back to Earth for the first time.

“The Artemis program will land the first woman and next man on the moon and bring them back safely to Earth, we are proud to contribute to this endeavor with all our know-how, expertise and passion,” Hammer says.

Related Content

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePlant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

Lockheed Martin completes Orion spacecraft capsule

The crew module capsule has been assembled onto the Orion service module for further testing before the Artemis 1 uncrewed mission to the moon.

Read MoreNASA's Orion completes first spaceflight test

NASA's uncrewed Orion spacecraft completed its first voyage to space on Dec. 5, traveling farther than any spacecraft designed for astronauts has been in more than 40 years.

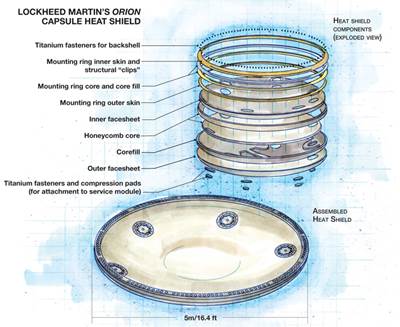

Read MoreOrion re-entry system: Composites displace metal

World’s largest heat shield updates metal design with out-of-autoclave process.

Read More

.jpg;width=70;height=70;mode=crop)