Plataine scheduler improves composites production efficiency for Multi-Ply Components

Multi-Ply is now able to cut planning time, optimize decisions for purchasing additional resources and automate short- and long-term planning of more than 10,000 tasks.

Plataine (Waltham, Mass., U.S.) announces that Multi-Ply Components Ltd. (Blackpool, U.K.), a designer and manufacturer of carbon fiber components for medical X-ray imaging in the medical market, has successfully implemented Plataine’s AI-powered Production Scheduler to enhance its production efficiency.

“By implementing our AI-powered solutions, Multi-Ply is scaling their operations to maximize resource utilization, achieve higher quality and drive growth,” Avner Ben-Bassat, president and CEO of Plataine, says.

Prior to deploying Plataine’s solution, Multi-Ply says its production planning process was fragmented and time-consuming, with the planner spending hours each week creating plans using a spreadsheet. Department managers had to then develop more detailed specific departmental plans. The manual process was laborious and lacked real-time visibility into order progress, causing delays in identifying and addressing unexpected issues on the factory floor. In addition, the spreadsheet could not support strategic decisions of buying new equipment and presenting the impact of future investments.

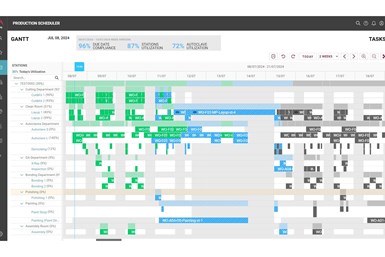

By implementing the Production Scheduler, Multi-Ply can automatically generate an optimized and detailed 3-month production plan within minutes. The work orders are automatically transferred from SAP to Plataine software via API. Plataine’s Production Scheduler efficiently manages more than 10,000 tasks across 40 stations and 19 departments, reducing the planners’ workload so they can respond to issues as they occur and keep the plan up to date. The solution also provides real-time visibility into production progress, enabling operators to report on task start and completion instantly, which can eliminate the need for daily updates and production meetings to spot issues. Multi-Ply’s production planner can now quickly respond to unexpected changes on the factory floor, improving throughput and overall operational efficiency.

The ability to run sandbox simulations also supports long-term planning and smart procurement decisions, enabling the production team to optimize decisions for purchasing additional resources, managing inventory efficiently and adding more shifts when necessary.

“The functionality to test various scenarios gives us the ability to justify the need and cost of additional resources,” says Lucas Morgan, technical and NPI director at Multi-Ply. “With Plataine, our production leaders have full visibility of production progress in real-time, enabling us to make data-driven operational and strategic decisions. This is a long-term journey together.”

Related Content

-

Siemens Gamesa, Airborne develop automatic preforming robot system for offshore wind blades

Danish-funded ALMA project furthers collaboration, adds new functionality, advanced sensor systems and digital twinning for reduced man-hours, waste and cost per blade.

-

Aerotech Academy Puglia is inaugurated at Leonardo Aerospace site in Grottaglie, Italy

Joining the Leonardo MaTeRIA Lab and Joint Lab with Syensqo, this aerostructures training course will be 75% materials science and structural design/analysis, 25% digital transformation and AI.

-

Modular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.