Purdue researchers develop new type of intelligent architected materials

Phase transforming cellular materials (PXCM) exhibit intelligent responses to external forces and stimuli, can dissipate energy to avoid damage and are being developed for transportation, military and other applications that can use composites.

Share

Read Next

Pablo Zavattieri, the Jerry M. and Lynda T. Engelhardt professor in civil engineering, lifts an aircraft runway mat made with new intelligent architected materials developed at Purdue University (right). In testing, the mats were capable of withstanding over 5,000 landing and takeoff cycles over a 60-day period while showing no signs of failure (left). Photo Credit: Purdue University

Researchers in Purdue University’s (West Lafayette, Ind., U.S.) Civil Engineering department have developed patent-pending intelligent architected materials that can dissipate energy caused by bending, compression, torque and tensile stresses, thereby avoiding permanent plastic deformation or damage. These materials may also exhibit shape memory properties that enable them to have actuation capacity. Avoiding damage makes the material reusable and improves human safety and structure durability in products across several industrial sectors.

Pablo Zavattieri, the Jerry M. and Lynda T. Engelhardt Professor in Civil Engineering, leads the research team that has developed this new class of intelligent architected materials. “These materials are designed for fully recoverable, energy-dissipating structures, akin to what is referred to as architected shape memory materials, or phase transforming cellular materials, known as PXCM,” explains Zavattieri. “They can also exhibit intelligent responses to external forces, changes in temperature and other external stimuli.”

Intelligent architected materials such as these have a wide range of potential applications due to their distinctive properties, Zavattieri adds. “These materials can change from one stable configuration to another, making them versatile and valuable for various applications including earthquake engineering, impact-resistant structures, biomedical devices, sporting goods, building structures and automotive components.”

Materials versatility and scalability

Virtually any material, including polymers, rubber, concrete and more, can be used to make the Purdue intelligent architected materials as long as they are designed to remain in the elastic regime. “While it’s true that more brittle materials present greater design challenges,” says Zavattieri, “consider this: One of my PhD students successfully crafted a single-unit cell using concrete, a material known for its brittleness in tension. Creating these intelligent materials is all about effective design, making material choices remarkably versatile.”

CW asked if it is possible to use fiber or nanomaterial-reinforced polymer composites with these architected shape memory materials/PXCM. “It is indeed possible to incorporate these advanced materials into composites,” says Zavattieri. “These materials are known for their unique mechanical properties, including the ability to change from one stable configuration to another depending only on their elastic properties and design, especially for stiffness and energy dissipation requirements. So, in principle, we can use any material. Using composites will allow us to achieve better performance as we can get better specific properties like higher stiffness per unit weight.”

Zavattieri and his team also have proven PXCM scalability. “We have produced intelligent architected materials as large as 12 inches, which are ideal for applications like building and bridge construction to absorb and harness energy,” he notes. “Conversely, we have created materials with unit cells smaller than the thickness of a human hair. This scalability opens up a world of possibilities from macro to micro applications.”

Drawbacks of traditional lightweight cellular materials

Cellular or foam materials are characterized by a porous microstructure or interconnected beams, columns or truss-like structures, with solid spaces and empty spaces that form a lattice or honeycomb arrangement. Examples found in nature include bone, cork, foam, honeycombs, sponge and wood.

“Manufacturers have applied the concept of cellular structures to create lightweight lattice structures in the aerospace industry, to enhance crash energy absorption in the automotive industry and to design protective packaging for delicate items in the transportation industry,” says Zavattieri. He adds that most of these materials have a single stable configuration.

“Changes in the cellular geometry as a result of an applied load typically will be limited either by the desire to prevent permanent deformation or the fact that it is impossible to return to the original stable configuration,” explains Zavattieri. “There is an unmet need for a material structure that has a more stable configuration.”

The new intelligent architected materials developed at Purdue redefine the concept of cellular materials, says Zavattieri. “We have engineered the topology of their inner building blocks, which are made of beams, columns, trusses and other elements. They are able to bend, twist, buckle and deform in highly controlled and programmable ways. These precisely tailored deformations give rise to emergent properties such as enhanced energy absorption, increased work capacity, morphing capabilities and adaptability. These properties open up innovative possibilities for various applications.”

Zavattieri and his colleagues have applied the compliant nature of cylindrical shells to create the materials. “Energy is dissipated via snap-through mechanisms, allowing for avoidance of plastic deformation,” he says. “Simulations were used to identify the relations between unit cell design parameters and deformation modes, and this knowledge was carried over to manufacture prototype specimens for validation. It was shown that energy dissipation and peak load capabilities could be optimized by changing ligament lengths and angles of inclination.”

Zavattieri’s research has been published in the peer-reviewed journals Engineering Structures, Extreme Mechanics Letters, Scientific Reports, Journal of Applied Mechanics, Matter, International Journal of Solids and Structures and Engineering Structures. His research has received funding from General Motors, ITAMCO (Indiana Technology and Manufacturing Companies), the National Science Foundation and the U.S. Air Force.

Aircraft runway mat applications

A collaboration between Zavattieri and ITAMCO has demonstrated use of PXCM in the development of new aircraft runway mats for temporary or expeditionary flight operations. The mats have top and bottom plates contain a combination of carbon fiber elements and 3D-printed metal elements, creating a hybrid material that offers high stiffness and strength while remaining lightweight.

This panel system is an alternative to conventional AM-2 panels and offers improved longevity and mechanical properties. Applications of this technology include rapid deployment of structures or runways for defense, public health and natural disaster response. Zavattieri and his team validated the lightweight 3D-printed panels through field tests.

“The objective of the research is to develop a robust sheet or roll technology that serves as an alternative to the AM-2 mat,” says Zavattieri. “AM-2 matting has served the U.S. military well since the Vietnam War, but the materials and technology in the ITAMCO-led research project will offer many benefits over current systems.”

Zavattieri says a portable and lightweight airfield mat must be easy to install and store yet capable of withstanding the stresses of repeated aircraft takeoffs and landings. “Products made with PXCM geometry have the ability to change from one stable configuration to another stable or metastable configuration and back again,” he explains. “This means the new runway mat could potentially heal itself, resulting in a much longer life span than a runway made with AM-2 matting. Another benefit is that debris on the runway will not hamper the runway’s performance with our technology. In testing, these mats were capable of withstanding over 5,000 landing and takeoff cycles over a 60-day period while showing no signs of failure. Current conventional runway mats fail at approximately 1,500 cycles. This durability means fewer replacements of the mats, which require fewer financial resources.”

Non-pneumatic tire applications

The U.S. Army has identified a critical need for the development and deployment of non-pneumatic tires (NPTs), which are not supported by air pressure and thus, are not prone to punctures or leaks. Zavattieri and his research team have developed a computer-based model supporting the use of the Purdue phase transforming cellular materials in the design of an NPT as specified by industry standards. Modeling and simulation results demonstrate feasibility of PXCM as a dynamic, elastically deformable solution for the design of NPTs, he says.

“This effort has shown that PXCM can provide good performance on paved surfaces and provide good adaptability to the off-road environment,” notes Zavattieri. “For military vehicles of interest, tires are designed to mitigate different-sized obstacles, loading conditions and variable terrain typically encountered in theater like sand, mud, gravel and snow. Modeling and simulation of designs demonstrate a PXCM-based NPT is capable of meeting performance requirements for both on-highway and off-road applications over varying load conditions and can resist loss of mobility due to material loss, up to 20%, resulting from ballistic/explosive threats or road debris. Model results suggest PXCM-based NPTs have the potential to extend vehicle capability and increase the probability of mission completion despite having sustained damage.”

Zavattieri disclosed the phase transforming cellular materials and their applications to the Purdue Innovates Office of Technology Commercialization, which has applied for patents to protect the intellectual property. Industry partners interested in commercializing the materials for the marketplace should contact Dipak Narula, assistant director of business development and licensing in physical sciences, at dnarula@prf.org.

Related Content

Co-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreRead Next

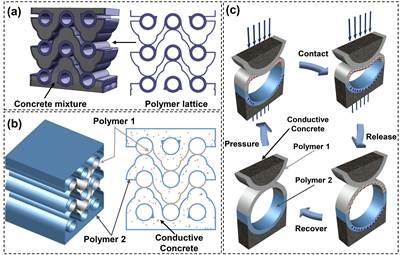

21st century concrete: composite metamaterial with super compressability, energy harvesting

Material comprising 3D-printed, auxetic, reinforced polymer lattices in conductive cement matrix can compress up to 15% and generate electricity for lightweight, mechanically tunable structures with energy harvesting and sensing.

Read MoreTechnology Innovation Institute AMRC explores novel metamaterial shapes for better shock, vibration shielding

Exploration of precisely engineered lattice structures including triple periodic minimal surfaces (TPMS) serve to develop more predictable, lightweight, high-performance sandwich cores.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)