Roboze reveals ceramic-filled Helios PEEK 2005 filament to the 3D printing sector

Ceramic reinforcement proves an ideal candidate for applications that require lightness, mechanical strength, heat resistance and highly complex geometry specifications.

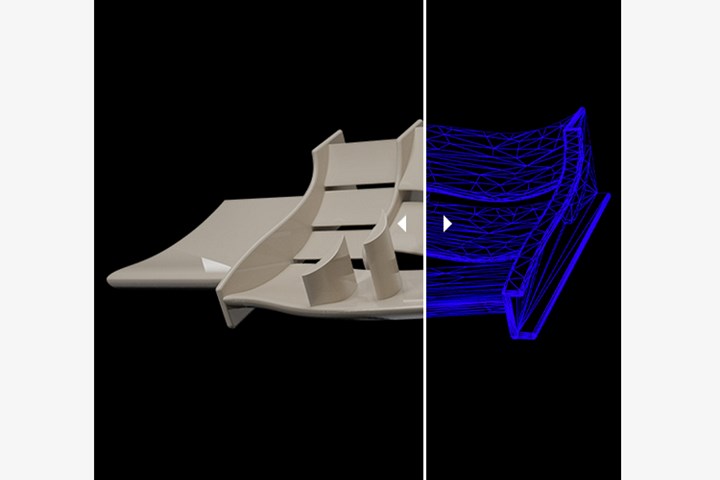

Photo Credit: Roboze

As a demonstration of its continued commitment to the research and development (R&D) of new metal replacement solutions for industrial 3D printing, including high-performance polymers and composites, Roboze (Bari, Italy and Houston, Texas, U.S.) introduces its new polyetheretherketone (PEEK) matrix composite: Helios PEEK 2005.

With the aim of offering new performance and application opportunities to its customers, Helios PEEK 2005 is a PEEK matrix composite material filled with ceramic. The filament is said to offer greater stability at high temperatures and increases the finished surface of parts printed with Roboze 3D printing solutions.

The ceramic phase has smaller dimensions when compared with carbon and glass fibers, says Roboze, making Helios PEEK 2005 ideal to produce components with complex geometries, characterized by thin walls. The monocrystalline nature of the reinforcement eliminates grain boundaries and minimizes crystallographic defects, maximizing its effectiveness. This feature is also fundamental for accelerating the time-to-market of end users, as it offers a reduction in post-processing times of more than 60% compared to other polymers and composites. Moreover, due to the intrinsic low thermal conductivity of the ceramic reinforcement, Helios PEEK 2005 exhibits high thermal insulation properties even when exposed to operating temperatures above 170°C. The printed parts are light, with a low electrical conductivity, suitable for applications where the insulation characteristic is a fundamental technical requirement.

“At Roboze, we have seen great strides with the use of our 3D printing technology in sectors including aerospace, energy and motorsports. We work closely with many of these regulated industries, supporting the integration of additive manufacturing [AM] technology from prototype to production,” says Simone Cuscito, CTO at Roboze. “Helios PEEK 2005 derives precisely from the needs of these industries and is an excellent candidate for applications that require specifications of lightness, mechanical strength and heat resistance.”

The new Roboze filament will be available in March 2022 on the Roboze 3D Parts Marketplace, the company’s on-demand 3D printing service. This is supported by a network of specialized centers, distributed around the world and equipped with the Roboze 3D printing technology.

Additional information will be shared during a webinar, organized by the Roboze team, scheduled for March 17, 2022 at 10 a.m. CDT/5 p.m. CET .

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Clean Sky 2 OUTCOME project demonstrates PEEK thermoplastic composite wingbox cover

Airbus Defense and Space, FIDAMC and Aernnova demonstrate out-of-autoclave, one-shot process for wingbox cover with integrated stringers for regional aircraft.

-

Eaton developing carbon-reinforced PEKK to replace aluminum in aircraft air ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.