Rock West delivers high-precision composite support tube for particle detection

Large carbon fiber and honeycomb core component, known as the barrel timing layer (BLT) tracker support tube, was delivered to Purdue as part of an upgrade to CERN’s general-purpose proton-proton collision detector for space research.

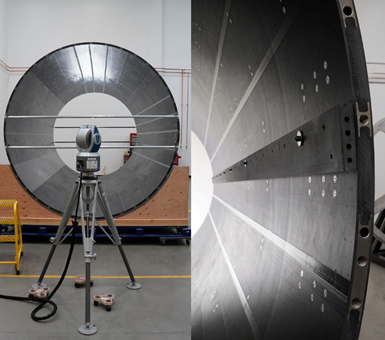

Rock West Composites (RWC, San Diego, Calif., U.S.) announces the delivery of the barrel timing layer (BTL) tracker support tube to Purdue University (West Lafayette, Ind., U.S.) this month. This large carbon fiber sandwich structure, destined for CERN (Geneva, Switzerland), a laboratory for particle physics, was designed by a joint team from Purdue University, led by Dr. Andy Jung and Dr. Ben Denos, and RWC led by John Marks. The collaborative effort met key performance parameters using the most cost-effective design. The hardware RWC delivered will be integrated with instrumentation from Purdue prior to delivery to CERN.

The carbon fiber tube supports the heart of an upgraded compact muon solenoid (CMS) detector, a “camera” with more than a billion pixels to record proton-proton collisions at extremely high energies with high resolution. In a few years, once fully commissioned, the upgraded CMS detector is expected to collect 10 times the data recorded than with use of conventional means, in the hunt for new particles to better understand the origins of the universe.

The BTL tracker support tube had to be manufactured from materials with extremely low radiation resistance, have a precise circular, cylinder structure, be strong and stiff and met an accelerated delivery schedule. Because the final tube had such challenging requirements, traditional tooling or manufacturing approaches would have been unaffordable.

Rather, innovative techniques were used, starting with the manufacture of curved, solid laminate arc segments rather than a full cylinder. Precision machined arc segment stiffeners help hold the arcs to strict dimensions once assembled. Low coefficients of thermal expansion are maintained in all three directions: radially, circumferentially and along the length of the tube.

Prior to making the full-scale tube, RWC built a version of the part with a full diameter but shorter in length as a technology demonstrator. RWC was presented with an Industry Gold Award from CERN in 2022 for this effort, and ultimately won the program from Purdue for the full-size hardware due to the success of the demonstration model and its affordability.

The delivered hardware is 5.3 meters long × 2.4 meters in diameter. It is constructed of ultra-high modulus prepreg and Nomex honeycomb core made with PMT-F6 cyanate ester resin. There are 1680 metallic inserts made of solid carbon fiber/epoxy, titanium and stainless steel, and it includes two 110 MSI carbon fiber (K13916/ F6) rails to support scientific instruments. Surface accuracy requirements were tested to 2.4 millimeters cylindricity in-house before shipment.

“We were excited to take on this challenging program and to know that we will be contributing to the advancement of humanity’s understanding the fundamental construct of matter,” John Marks, VP of product development, says. “Our work on the demonstration model and final hardware pushed our team’s technical skills to the limit, and we couldn’t be prouder of their performance on this program.”

Related Content

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.