Rock West Composites completes composites-intensive EOI Space telescope structure

Delivery of mirror mountings and stress-free module support meets LEO constellation optical payload requirements within six-month design, analysis and fabrication schedule.

Share

Read Next

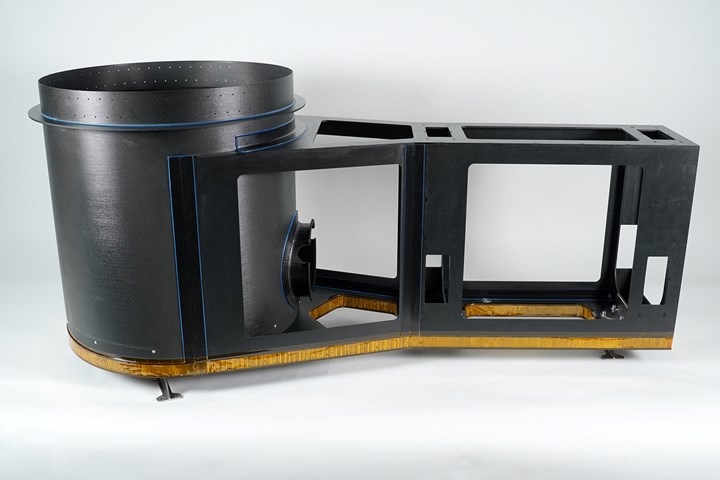

Large aperture telescope structure delivered to EOI Space. Photo Credit, all images: Rock West Composites (RWC)

Rock West Composites (RWC, San Diego, Calif., U.S.) announces that it has delivered a large apeture space telescope structure to its customer, EOI Space (Louisville, Colo., U.S.) for its very low Earth orbit (LEO) constellation that is currently in development.

RWC provided engineering design, analysis and fabrication services for this stable structure within a compressed 6-month schedule while meeting tight requirements. Once integrated with its optics and detectors, the telescope will provide near-real-time ultrahigh-resolution earth imaging services to EOI Space’s wide customer base.

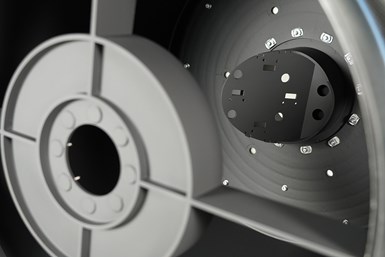

The telescope structure features mountings for three separate mirrors, as well as stress-free support of the imaging module and a decoupled mount to the spacecraft bus structure. Constructed of high modulus unidirectional carbon fiber-reinforced cyanate ester prepreg, aluminum honeycomb core and metallic inserts, the telescope was fabricated to meet the specific needs of EOI Space’s distinctive optical payload. While using the commonality of composite components to cut down on part count for the first deliverable, future iterations will be optimized for weight and producibility.

RWC provided clean sheet engineering and design for this telescope structure including static, quasi-static, modal, acoustic, thermal and deflection analysis to ensure all requirements were met for launch, orbital and operational conditions.

According to Geoff Pinto, program manager for the space telescope project at RWC, “We leveraged our deep background in stable space structure fabrication to achieve the demanding requirements of this program, and we were able to exceed those demands for our customer.”

For related content, read “Rock West Composites delivers composite assembly fixtures for NASA PASS program.”

Related Content

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Microwave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.