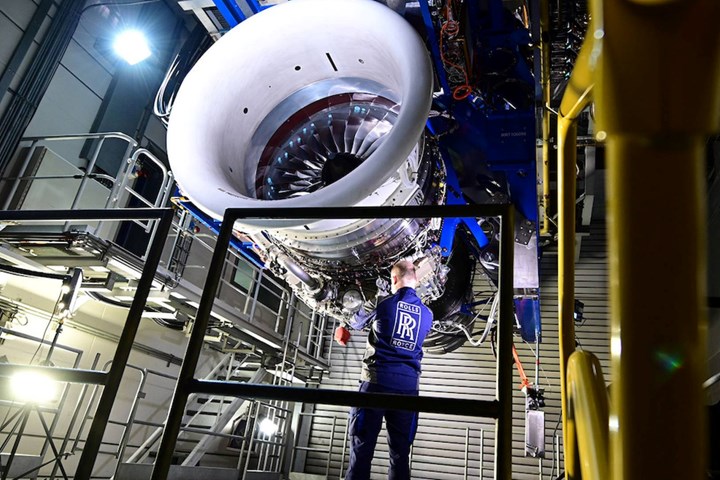

Rolls-Royce reports strong progress in Pearl 10X testing

Composites-intensive aeroengine culminates 1,000+ hours of testing with recent ultra-low emissions ALM combustor, accessory gearbox development, so far proving its reliability and performance requirements.

According to Rolls-Royce (London, U.K.), its Pearl 10X engine development program to power Dassault Aviation’s (Paris, France) flagship, the Falcon 10X, has made good progress, and has successfully cumulated more than 1,000 testing hours, both on the Advance 2 demonstrator and the Pearl 10X engine configuration. The engine’s composite package, secured in Feb. 2022 by FACC AG (Ried im Innkreis, Austria), includes supply of the fan track liners, spinner and cable bushing for the turbofan engine.

The first dedicated Pearl 10X test engine ran for the first time earlier this year and surpassed its target thrust levels on the first test run, making it the most powerful business aviation engine in the Rolls-Royce portfolio, says the company. All testing conducted so far has proved the reliability of the engine and shown it will meet performance requirements.

So far, the development program has included the rigorous testing of the new, ultra-low emissions ALM combustor, which is compatible with 100% sustainable aviation fuel (SAF) and the new accessory gearbox, which enables for higher additional power extraction. One of the next milestones will be the first full powerplant, including its bespoke Spirit AeroSystems (Wichita, Kan., U.S.) nacelle, EBU and mount system, entering the test program later this year.

“The combination of highly efficient power and outstanding environmental performance of the Pearl 10X is in a class of its own and will support Dassault’s Falcon 10X in setting new standards in the ultra-long-range corporate jet market,” Dr. Dirk Geisinger, director business aviation, Rolls-Royce, emphasizes.

The Pearl 10X features an efficient Advance2 engine core, combined with a high-performance, low-pressure system, resulting in a thrust of more than 18,000 pound-force. Compared to the last generation of Rolls-Royce business aviation engines, the Pearl 10X offers a 5% higher efficiency, while delivering outstanding low noise and emissions performance.

Related Content

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.