Roth develops filament winding machine for Ariane 6 rocket components

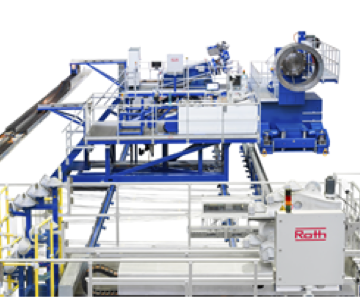

Designed specifically to handle the Ariane 6 boosters, Roth’s filament winding plant is one of the world’s largest machines of its kind.

Roth Composite Machinery (Steffenberg, Germany) announced June 26 a filament winding plant developed in close cooperation with space propulsion system manufacturer Avio (Colleferro, Italy), who is using the new Roth machine to manufacture the propulsion rockets for the Arianespace (Evry, France) Ariane 6 next generation launch vehicle.

The boosters of Ariane 6 are about 15 m long and have a diameter of up to 3.6 m. The booster case is completely made of carbon fiber, which replaces the steel casing of the previous version used for the Ariane 5.

Designed specifically to handle the boosters, Roth’s filament winding plant is one of the world’s largest machines of its kind. It weighs around 100 tons and with a maximum length of 17 m and a diameter of 3.6 m, the winding mandrel weighs around 120 tons. The machine is equipped with three carriages for three different winding processes – each carriage has a length of 7.4 m and moves up to 90 m per minute.

The first carriage is used for winding heat protection tape onto the mandrel in moldless composite construction (first layer inside the booster). After the vulcanization of the tape, the Towpreg winding process is effected by using the second carriage.

The third carriage is equipped with a fiber delivery head for automated tape laying (ATL) being patented by Avio. This technology enables the exact laying of the tape resulting in complex geometrical shapes for the attachment parts of the boosters. The trimming of the tape is carried out by means of an ultrasonic cutting head. The ATL technology was developed by Avio together with Roth and another Italian partner.

From 2020, the Ariane 6 is expected to carry out aerospace transports of satellites for the European Space Agency ESA. The weight of its booster stages is said to be reduced by up to 35% due to the filament winding process.

Related Content

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.