Schmidt & Heinzmann camera system awarded 2022 AVK Innovation Award

“Pole Position” uses polarization properties to detect the positioning and orientation of carbon fibers during the cutting and stacking process, reducing waste and enhancing sustainability.

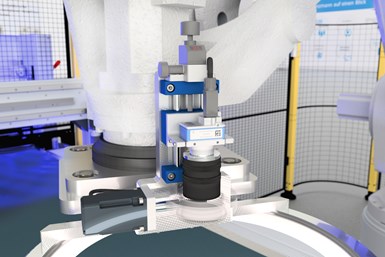

Camera system on cutting and stacking cell. Photo Credit, all images: Schmidt & Heinzmann GmbH & Co. KG

Schmidt & Heinzmann (Bruchsal, Germany) was awarded second place in the “Innovative Processes and Methods” category at this year’s AVK (Augsburg, Germany) Innovation Award, which took place at the JEC DACH Forum at the end of November in Augsburg. The novel camera system, “Pole Position,” which detects the positioning and orientation of carbon fibers, can be used in the automated production of carbon fiber-reinforced polymer (CFRP) components. In the future, the system will be integrated directly into the company’s cutting and stacking cells, which cut fabrics from dry fibers and consolidate the individual layers into a stack.

Until recently, the position and orientation of carbon fiber material in the cutting and stacking process have been measured either with conventional camera systems or by using laser or color sensors. When using conventional camera systems, homogeneous illumination of the recording area is necessary due to the reflection of the carbon fibers, which is difficult to implement, especially with large components. Alternately, laser and color sensors only provide point measurements along the material edge; the uneven edges of the carbon fibers can result in result in significant measurement errors, which also makes this technique unsuitable.

Schmidt & Heinzmann’s camera system takes advantage of the polarization properties of the carbon fibers, which means that the light reflection and absorption of the fibers are irrelevant, the company claims. The system determines the change of intensity with respect to the polarization direction. This relative value can also be determined under changing lighting conditions. A newly developed software then separates the resulting image into polarized and unpolarized areas, enabling the background to be hidden and the component contour to be measured. With an accuracy of ±0.38 millimeter, the system is reported to perform significantly better than conventional systems with an accuracy of ±4 millimeters.

When using the camera system, users primarily benefit in terms of sustainability, the company notes. Precise contour determination on the NC cutting table allows reduction of edge trimming by up to 85%. When stacking the cuts, the individual layers can be placed on top of each other even more precisely. This exact positioning is a prerequisite for producing preforms with final contour. Therefore, trimming of the components is no longer necessary in the wet compression molding process, for example, which saves 5-10% of the raw materials used (carbon fibers and resin). By eliminating the two process steps “trimming” and “sealing,” investment costs as well as energy costs of these substeps can also be saved.

The announcement makes this the fourth innovation award Schmidt & Heinzmann have received within two years. “We are pleased that another innovation from our product area ‘Cutting & Stacking’ has been awarded,” CEO Matthias Feil says, “especially as the market acceptance for this product is very good so far. The first systems have already been sold, others are in the quotation phase.” Last year, the Cutting & Stacking solutions themselves won the ThinKing Award from the Landesagentur für Leichtbau Baden-Württemberg (State Agency for Lightweight Design), the semi-finished production line “Cube” was selected as a JEC Award finalist and the company itself was named a Top 100 Innovator.

Related Content

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MorePlant tour: Arris Composites, Berkeley, Calif., U.S.

The creator of Additive Molding is leveraging automation and thermoplastics to provide high-volume, high-quality, sustainable composites manufacturing services.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreRead Next

JEC Group, AVK launch new composites event for the DACH region

JEC Forum DACH, which will take place Nov. 23-24, 2021, will annually highlight and support the composites industry to build business, connect major players and highlight the industry’s dynamics.

Read MoresensXPERT Digital Mold earns 2022 AVK Innovation Award

Data-driven sensor technology optimizes and increases composites manufacturing efficiencies in real time, achieved through collaborative network.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More