Skyrora, Spirit AeroSystems collaborate to enhance future U.K. launch capabilities

Spirit’s aerostructures expertise will guide transition from development to full-scale production of Skyrora’s orbital launch vehicles, including the composites-intensive SkyLark L.

Private space company Skyrora Ltd. (Edinburgh, U.K.) and Spirit AeroSystems (Belfast, Northern Ireland) have announced a collaboration on orbital launch capability. The partnership will enable Skyrora to transition its orbital launch vehicles from development to full-scale production using Spirit’s highly adaptive manufacturing and testing solutions in metallics and composites, in addition to localizing its supply chain.

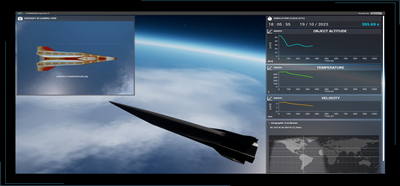

Skyrora is developing an agile, end-to-end, launch service to provide access to space for small satellites globally. Having conducted a test launch of the suborbital, single-stage Skylark L vehicle in October 2022 as part of the company’s incremental learning approach to launch, Skyrora says it is on track to become the first U.K. company to vertically launch satellites from the U.K., expecting to conduct up to 16 launches per year once operating at scale.

SkyLark L is 11.65 meters in length and 0.7 meters in diameter, with a payload mass of 50 kilograms. Like Skyrora’s Skyrora XL 22.7-meter three-stage, light class launch vehicle (read more on this below), the craft uses fiberglass, carbon and aramid fibers reinforced with polymers such as epoxy, vinyl ester and polyester resins.

“By collaborating with innovative partners like Spirit, Skyrora will be able to access manufacturing and testing capacity right here in the U.K.,” Volodymyr Levykin, CEO and founder of Skyrora, says. “Historically, space has not been an environmentally friendly industry, but we are committed to being a responsible player that continues to foster talent and skills nationally as the ambitious New Space economy goes from strength to strength.”

Spirit’s presence in U.K. space is growing. Its broad offering of manufacturing and testing solutions, at both its Scotland and Northern Ireland facilities, brings significant industrial capacity to Skyrora’s launch proposition. Leveraging Spirit’s aerostructures expertise, the companies will explore opportunities to transition Skyrora’s orbital launch vehicles from development to full-scale production.

The space tug, based on the upper stage of the Skyrora XL launch vehicle enables multiple environmental benefits, such as allowing multiple payloads to be deployed in their chosen orbits from the same launch, reducing the number of rocket launches required. Photo Credit: Skyrora and Skyrora website

The U.K. government has made orbital launch a key priority, with the National Space Strategy outlining plans to secure an increased portion of a global space economy expected to be worth £490 billion by 2030. “This collaboration between Skyrora and Spirit clearly demonstrates the attractiveness of the U.K.’s thriving launch sector and the growing interest from both U.K.-based and international companies,” Matt Archer, director of launch, UK Space Agency, adds.

Collaborative goals also include the research of space technologies, particularly in additive manufacturing. Skyrora will provide Spirit with access to Skyprint 2, claimed to be the largest in-house hybrid 3D printer of its kind in Europe. Located in Skyrora’s manufacturing facility just outside Glasgow, research enabled by Skyprint 2 has the potential to unlock a localized supply chain to reduce costs and lead times for Spirit, bolster industrial cooperation and promote growth within the U.K. space sector.

Related Content

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreMicrowave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

Nominal Systems digital twin prototype to progress Hypersonix Dart AE aircraft

One-to-one virtual simulation will enable Hypersonix to capture real flight data of its hypersonic vehicle during maiden flights prior to production.

Read MoreImpulse Space to launch first orbital service vehicle in 2023 using CFRP tanks

Interview with COO discusses carbon fiber composites in tanks, vehicles and their role in space commerce as part of rapidly growing New Space economy.

Read MoreFirefly Aerospace completes composite Blue Ghost lunar lander

First of two lunar missions under NASA’s CLPS initiative will launch in 2024 and conduct diverse technology demonstrations and scientific investigations on the moon’s surface.

Read More