SPE names winners of 2015 Automotive Innovation Awards Competition

Continental Structural Plastics' TCA Ultra Lite sheet molding compound (SMC) for composite body panels was the Materials category and Grand Award winner.

The Automotive Division of the Society of Plastics Engineers (SPE, Troy, MI, US) announced on Nov. 11 the category and Grand Award winners for its 45th-annual Automotive Innovation Awards Competition, the oldest and largest recognition event in the automotive and plastics industries. The Materials category winner was selected as this year's Grand Award winner, representing the year's most innovative use of plastics by a blue-ribbon panel of judges.

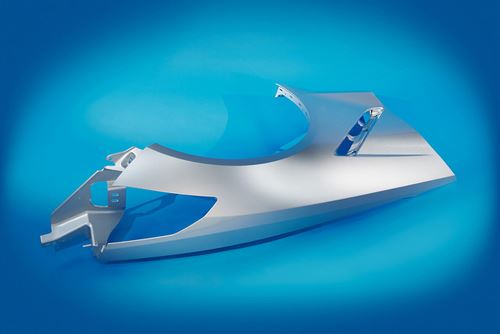

GRAND AWARD & CATEGORY: Materials

ULTRALIGHT CLASS A BODY PANELS

- OEM Make & Model: 2016 General Motors Co. Chevrolet Corvette sports car

- Tier Supplier/Processor: Continental Structural Plastics

- Material Supplier / Toolmaker: Continental Structural Plastics / Century Tool & Gage,

- Paragon Die & Engineering Co.

- Material / Process: TCA Ultra Lite SMC / compression molding

- Description: A new 1.2 SG SMC eliminated 9 kg of body-panel weight after a running change from a mid-density grade, where no tooling changes were required. Suitable for Class A or structural components, the new composite offers 28% mass reduction vs. mid-density (1.6 SG) grades and 43% vs. conventional (1.9 SG) SMC. It provides greater benefits vs. metal, including reduced weight and tooling costs, enhanced design flexibility, corrosion and dent resistance, and superior surface finish. Key to achieving the ultralow density was replacement of CACO3 with hollow-glass microspheres and use of a proprietary surface treatment to improve the resin/reinforcement interface.

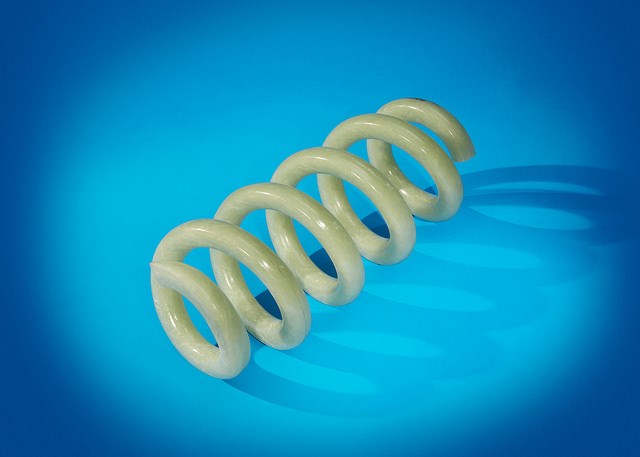

CATEGORY: Chassis/Hardware

FIBERGLASS/EPOXY COMPOSITE COIL SPRING

- OEM Make & Model: 2015 Audi AG Audi A6 Avant wagon

- Tier Supplier/Processor: S. Ara Composite S.A.S.

- Material Supplier / Toolmaker: Hexion Inc. / not stated

- Material / Process: Epikote epoxy + fiberglass /modified filament winding

- Description: This weight-saving epoxy/fiberglass composite coil spring is the first of its kind to be used in the suspension system of a series-production vehicle. Using a patented, modified filament winding process, the application replaced traditional steel coil springs, reducing weight 40% and enabling the suspension system to react more quickly to changing road surface conditions, thereby improving vehicle handling and NVH. Significant work was done on resin chemistry and resin/fiber interface to ensure efficient load transfer and long-term mechanical performance, as well as finding an efficient, cost-effective production method capable of meeting build volumes.

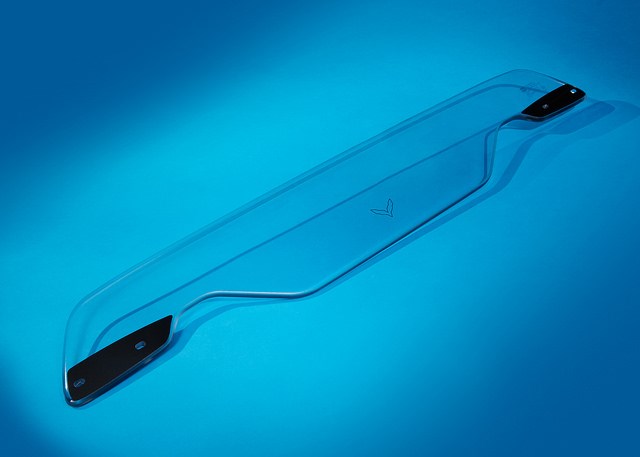

CATEGORY: Aftermarket

TRANSPARENT LIGHTWEIGHT WIND DEFLECTOR

- OEM Make & Model: 2016 General Motors Co. Corvette Stingray convertible sports car

- Tier Supplier/Processor: Polytec FOHA Inc. / SABIC

- Material Supplier / Toolmaker: SABIC / Pace Machine Tool, Inc.

- Material / Process: Lexan 9043 PC with Exatec 900 coating / CNC-trimmed sheet

- Description: This is the first use of a self-mounted, transparent and frameless wind deflector for convertible cars that meets AS2 ANSI and ECE requirements. The steeply raked design minimizes air turbulence and noise when the top is down. Replacing glass with PC lowered mass 33% and allowed a contoured shape to be achieved that would have been difficult and costly in glass. A laser-etched monogram under the surface is unobtrusive to vision during driving, yet visible during inspection and meets regulatory requirements for glass marking. A plasma coating enhances scratch, chemical, and UV resistance for long use life.

CATEGORY: Body Exterior

PUSH-TO-RELEASE EXTERIOR SERVICEABILITY FASTENER

- OEM Make & Model: 2015 Ford Motor Co. Ford Mustang sports car

- Tier Supplier/Processor: ITW Deltar Fasteners

- Material Supplier / Toolmaker: Ascend Performance Materials, LLC/ A&P Tool, Inc. & M&M Tool and Mold, LLC

- Material / Process: PA 6/6 / injection molding

- Description: Compared to other easy-service fasteners, which have twist heads to release, this injection molded PA 6/6 fastener only requires that you push the center pin to the service position to remove. This fastener cannot back out or be removed from the installed position without deliberate actions by the customer. The pin and body are designed to not be easily separated; however, the fastener is reusable, unlike other push pins that become damaged in the process of removal. It meets EU lamp serviceability requirements, reducing the time needed to remove the fastener by 90% without tools.

CATEGORY: Body Interior

REAR-SEAT FOLDING HEAD RESTRAINT

- OEM Make & Model: 2015 Ford Motor Co. Ford F-150 pickup

- Tier Supplier/Processor: Windsor Machine Group / Hawk Plastics Ltd.

- Material Supplier / Toolmaker: ExxonMobil Chemical Co. / IRC Engineering

- Material / Process: PP copolymer / injection molding

- Description: This rear seat, folding head restraint eliminates a welded steel structure and replaces it with a single-piece, living hinge plastic core as its main structural component. As a result, thickness is reduced 33 mm for improved comfort and rear visibility; mass is reduced 624 g/vehicle, manufacturing complexity is significantly reduced (eliminating the need for special tooling processes thanks to consolidation of 5 parts into 1); tooling costs are lowered; and piece price is reduced $1.50 USD/vehicle, while still meeting or exceeding all global safety requirements.

CATEGORY: Environmental

SEAT FABRIC FROM RECYCLED MATERIALS

- OEM Make & Model: 2015 Ford Motor Co. Ford F-150 pickup

- Tier Supplier/Processor: Johnson Controls Inc. / Sage Automotive Interiors

- Material Supplier / Toolmaker: Unifi Manufacturing, Inc. / not stated

- Material / Process: Repreve PET / Multiple

- Description: The fiber used in this innovative seat fabric is made from a hybrid blend of 100% recycled materials, including post-industrial fiber and post-consumer water bottles. The fabric meets Ford design and comfort requirements without any compromise in quality, durability, or performance. The switch from virgin fiber was achieved at cost parity, while providing significant environmental benefits, including diverting over 5-million water bottles from landfills just this year. To help close the loop further, there are now PET bottle collection bins installed at the Ford Research & Engineering campus. The bottles are recycled to help form this fiber.

CATEGORY: Powertrain

HEATED-TIP FUEL INJECTOR

- OEM Make & Model: 2015 Honda Motor Co. Honda Fit subcompact and City sedan

- Tier Supplier/Processor: Delphi Powertrain

- Material Supplier / Toolmaker: DuPont Automotive / Coltelleria Baldi

- Material / Process: Zytel HTN54G35EF BKB336 PPA / injection molding

- Description: An electrical heater within the injector is energized by the vehicle controller, rapidly heating the ethanol fuel and dramatically improving vaporization while reducing emissions. Ink materials used in construction of the heater, body design, the ink-printing process on the body, and overmolding with PPA (which was designed for flow, heat resistance, and electronic compatibility) were all key to the success of this application. The technology saved $60 USD/vehicle as well as 8.8 kg, while improving cold starts on E100 fuel and eliminating the need for a redundant gasoline fuel system on the vehicle.

CATEGORY: Process/Assembly/Enabling Technologies

IMX INSTRUMENT PANEL

- OEM Make & Model: 2014 Hyundai Motor Group Hyundai i20 supermini

- Tier Supplier/Processor: Hyundai-Mobis / HanilEhwa

- Material Supplier / Toolmaker: Hanwha L&C / Hyundai-Motor Co.

- Material / Process: Multiflex 3202 TPO / compression-injection molding

- Description: To eliminate scratches and a hard "plastic" feel, a 2-shot compression-injection soft IP was developed. The back-foamed TPO foil is compression-injected with the PP substrate, which in turn is integrally injection molded with the TPO passenger-side airbag door. All the work is done in a single tool. To increase foam softness and stability of the integral injection molding, the TRIZ method and design of experiments tools were used. The resulting part saves $10 USD/vehicle and reduces mass 300g.

CATEGORY: Safety

FLOOR ROCKER REINFORCEMENT

- OEM Make & Model: 2015 FCA US LLC Jeep Renegade SUV

- Tier Supplier/Processor: Proma Group / Redstamp

- Material Supplier / Toolmaker: SABIC / Redstamp

- Material / Process: Noryl GTX 910 MPPE/PA / injection molding

- Description: An optimized MPPE/PA 6 honeycomb geometry in a plastic/metal hybrid proved to be a very efficient energy-absorbing crash-box structure in this floor rocker reinforcement. Not only is the component E-coat capable, but it is very easy to assemble into the vehicle's BIW. Since the plastic honeycomb is integrally attached to two steel flanges during injection molding, no structural adhesives are needed. The mixed-material solution took 1 kg of weight out of the BIW, saved approximately 10%, and contributed tooling savings vs. previous steel solutions.

Category and Grand Award winners selected from among these finalists during the Blue Ribbon judging by a group of journalists, academics and retired industry chief engineers were announced at the Automotive Innovation Awards Gala on Nov. 11, 2015, at Burton Manor in the suburbs of Detroit.

Related Content

COMPINNOV TP2 project promotes use of thermoplastics in aerospace

Completed in 2023, COMPINNOV TP2 explored thermoplastic composites, enhancing the understanding between prepregs and production methods to foster the potential for French aerospace innovation.

Read MoreGKN Aerospace, Joby Aviation sign aerostructures agreement

GKN Aerospace will manufacture thermoplastic composite flight control surfaces for Joby’s all-electric, four-passenger, composites-intensive ride-sharing aircraft.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreSmartValves offer improvements over traditional vacuum bag ports

Developed to resolve tilting and close-off issues, SmartValves eliminate cutting through vacuum bags while offering reduced process time and maintenance.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More