Swinburne University of Technology opens industry-spanning R&D hub

AIR Hub plans to create innovative materials, manufacturing processes to lightweight and automate production of aerostructures and space systems.

Swinburne University of Technology (Melbourne, Australia) is launching an Aerostructures Innovation Research Hub (AIR Hub) with the support of $12 million in funding from the Victorian Government’s Higher Education State Investment Fund. Led by Swinburne, AIR Hub plans to bring together aerospace research, design and manufacturing leaders to work on real-world design and manufacturing problems for the next generation of air mobility.

AIR Hub will create innovative materials and manufacturing processes for passenger planes, air cargo and the space industry. It will also accelerate electric clean energy vertical takeoff and landing air vehicles (eVTOL). AIR Hub is also working toward lightweighting and automating the production of space systems like the rockets used to launch satellites, as well as drones and eVTOLs.

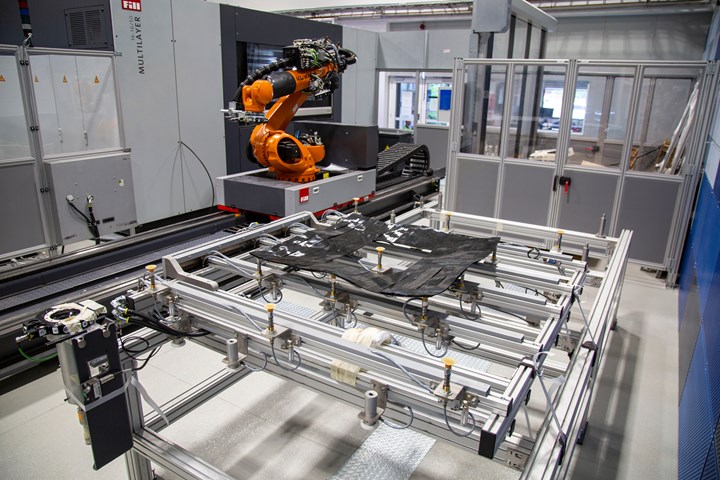

As part of the design and manufacturing process, AIR Hub will use artificial intelligence (AI), augmented reality, virtual reality, machine learning and collaborative robots (cobots) to support Australia’s capabilities to manufacture aerostructures.

AIR Hub’s industry partners include Boeing (Chicago, Ill. U.S.), Quickstep (Sydney, Australia), CableX (Victoria, Australia), Furnace Engineering (Victoria), Shoal (Adelaide, Australia) and Marand Precision Engineering (Moorabbin, Australia), as well as research partners CSIRO (Canberra, Australia), Monash University (Melbourne, Australia) and the University of Stuttgart (Germany) and ARENA 2036 (Stuttgart, Germany), combining with Swinburne’s research teams.

Facilities across Victoria, including the Swinburne-CSIRO Industry 4.0 Testlab for Composite Additive Manufacturing in Clayton and the manufacturing sites of key industry partners, will support AIR Hub’s R&D activities.

According to Swinburne’s vice chancellor and president, Professor Pascale Quester, AIR Hub will also research and develop capacity for hydrogen storage on aircraft and eVTOL air vehicles, enabling it to make use of greener fuels and help meet global zero-emission targets.

Related Content

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Next-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.