Teijin, Fujitsu to develop blockchain-based commercial platform for recycled materials manufacturing

The platform aims to enhance the environmental value of recycled FRP materials for manufacturers through life cycle assessment calculations and more reliable information management.

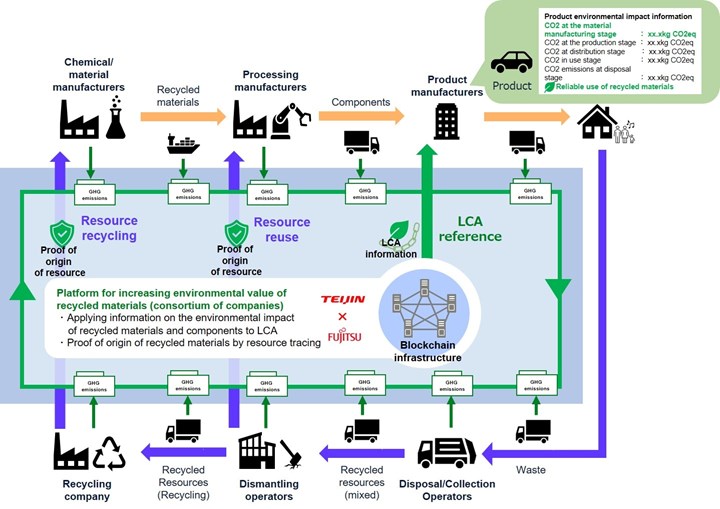

Teijin Ltd. (Tokyo, Japan) and Fujitsu Ltd. (Tokyo) have launched a joint project to realize a blockchain-based commercial platform for enhancing the environmental value of recycled materials for manufacturers, in addition to solving the challenges of more reliable information management such as transparency and traceability. As a first step in this collaboration, Teijin and Fujitsu will start full-scale trials with fiber-reinforced plastics (FRP) within fiscal year 2022, materials which the companies say will require more advanced, environmentally conscious design efforts — a design that takes into account the entire life cycle of a product and aims to reduce its environmental impact — in the future. Based on the results of these trials, the partners will consider expanding the scope of the project for other types of materials.

The collaboration will promote environmentally conscious designs by leveraging Teijin’s life cycle assessment (LCA) calculation method for measuring the environmental impact of manufacturing processes across the value chain, as well as Fujitsu’s blockchain technology to collect and track primary data on environmental impact (including GHG emissions) to deliver reliable, transparent traceability.

According to Teijin, the new platform will promote the use of recycled materials and environmentally friendly designs by providing manufacturers who design products from recycled materials with accurate information about their environmental footprint, including proof of origin of recycled materials and data on greenhouse gas (GHG) emissions.

This joint effort demonstrates the two companies’ commitment to contributing to the realization of the common global goal of a carbon-neutral future and a circular economy. Teijin strives to provide innovative, people-centered solutions that improve peoples’ quality of life. Fujitsu is promoting “Sustainable Manufacturing” to achieve growth through the coexistence of people and the earth as one of its key focus areas under its global business brand, Fujitsu Uvance.

The two parties expect to further promote discussions and field trials with partner companies and organizations that support this initiative to contribute to the realization of carbon neutrality on a corporate and global level.

Related Content

-

Aerotech Academy Puglia is inaugurated at Leonardo Aerospace site in Grottaglie, Italy

Joining the Leonardo MaTeRIA Lab and Joint Lab with Syensqo, this aerostructures training course will be 75% materials science and structural design/analysis, 25% digital transformation and AI.

-

ST Engineering MRAS presents initiatives to drive autoclave efficiency, automation

During a JEC World 2024 panel discussion, the company revealed ways in which it is maximizing throughput and efficiency of its autoclaves and enhancing composites production processes.

-

Com&Sens presents workshop on fiber optic sensing for COPVs

Three-day hands-on workshop from June 11-13 in Leuven, Belgium, will equip participants with a better understanding of fiber optic sensing technology for digital manufacturing of composite tanks.