Teijin highlights composites initiatives targeting carbon neutrality

Carbon fiber LCA methods, improving material carbon footprint and overall lightweighting opportunities for customers are just a few ways in which the Teijin Group expects to meet its 30% emissions reduction target.

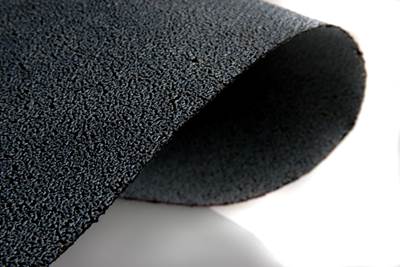

Teijin is capable of performing lifecycle assessments of Tenax carbon fibers. Photo Credit, all images: Teijin Group

As industry, governments and academia make efforts to reduce their environmental impact, so, too, does the Teijin Group (Tokyo, Japan), actively working to provides innovative composite solutions for enhanced quality of life and minimize negative impact on the environment or society through its business activities. Teijin considers environmental management to refer to management that reduces the environmental impact over the entire lifecycle of the product, including all processes from material procurement to production, product use and disposal.

Teijin’s long-term environmental targets have been adapted to a 30% reduction, with an additional target of 15%, specifically aimed at reducing the portion of emissions that accounts for more than two-thirds of the overall supply chain. The company’s targets for greenhouse gas (GHG) emissions are validated as science based targets (SBT). The objective of SBT is to help achieve the Paris Agreement’s goal of limiting global temperature rise to well-below 2°C above pre-Industrial Revolution levels, which is expected to significantly reduce the risks and impacts of climate change.

Teijin has established a method for calculating CO2 emissions during the manufacture of Tenax carbon fibers, which has made it possible to conduct lifecycle assessments (LCA) of all carbon fiber materials offered by Teijin. The company calculates its own manufacturing processes and evaluates the carbon footprint of its customers’ manufacturing process with this method.

Teijin Aramid (Arnhem, Netherlands), a core aramid business of the Teijin Group, has improved the carbon footprint of its para-aramid product, Twaron, by 28% compared to 2014 according to the applicable ISO standards 14040 and 14044, the company says. The benefit of using Twaron can be calculated economically and environmentally by the Customer Benefit Model (CBM) developed by Teijin Aramid.

Teijin’s lightweighting solutions also enable it to help reduce gas emissions and improves overall fuel performance, meaning yes impact. One example from Teijin Automotive Technologies (Auburn Hills, Mich., U.S.) is TCA Ultra Lite, a 1.2 specific gravity ultra-lightweight sheet molding compound (SMC) formulation that uses glass fiber-reinforced plastic (GFRP). Carbon fiber-reinforced thermoplastic (CFRTP) Sereebo is another example. Compared to thermosetting resins, which require several minutes to several hours to mold, Teijin says it has been able to significantly reduce these molding times with thermoplastics; this has led to the establishment of a mass production technology that is reported to mold CRRP in only one minute.

In addition to this, the Teijin Group’s fibers and products converting company Teijin Frontier offers to apparel manufacturers numerous products that help reduce CO2 emissions, including EcoPET, a recycled polyester fiber that utilizes used PET bottles and fiber scraps as raw materials, and Solotex, which uses plant-derived ingredients for a portion of its polymers. Teijin Frontier has also developed a system to calculate CO2 emissions within the polyester fiber manufacturing process, thereby enabling the implementation of LCA. It will gradually expand the scope of its operations to cover more textiles, including those used for weaving and dyeing, while working with its partner companies to evaluate the entire lifecycle of polyester fiber products.

Related Content

Hexagon Purus Westminster: Experience, growth, new developments in hydrogen storage

Hexagon Purus scales production of Type 4 composite tanks, discusses growth, recyclability, sensors and carbon fiber supply and sustainability.

Read MoreCirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreRead Next

NCAMP qualifies Teijin carbon fiber-reinforced thermoplastics

This represents the first qualification of a carbon fiber fabric-reinforced thermoplastic composite material by the National Center for Advanced Materials Performance (NCAMP).

Read MoreInside Teijin’s thermoplastic tape expansion

Teijin is qualifying its second thermoplastic tape line in Heinsberg, Germany, that will significantly expand the company’s presence in this material segment.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More