Toray creates world’s first porous carbon fiber with nano-sized continuous pore structure

Applications include lighter structures for batteries, H2 production and CO2 recycling.

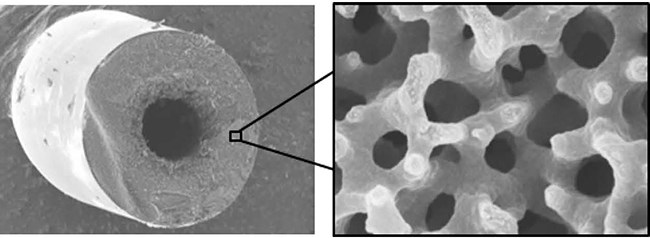

Porous carbon fiber with continuous pore structure. Source | Toray

Toray Industries Inc. (Tokyo, Japan) announced that it has created the world’s first porous carbon fiber with a nano-sized continuous pore structure. The fiber is designed for use as a support layer in advanced membranes used for greenhouse gas separation and hydrogen production, making them lighter and more compact for enhanced performance.

The company will continue R&D for this new material and is collaborating other entities to develop applications. Prospective applications include electrode materials and catalyst carriers (base substances for fixing other substances) in high-performance batteries.

According to Toray, absorption- and adsorption-based facilities conventionally separate carbon dioxide, biogas, hydrogen and other gases, but the issue with such setups, is that they are large and consume a lot of energy, resulting in heavy carbon dioxide emissions. Gas separation methods employing membranes have thus attracted considerable attention, but so far, no membranes have yet been developed that combine satisfactory gas separation performance and durability.

Toray’s new carbon-based material is said to be chemically stable and offers optimal gas permeability. The material employs thin, flexible fibers, so gas membrane modules can house many of them while remaining compact and light. Such support makes it possible to combine a range of gas separation layers. Toray looks to contribute to commercialization of advanced separation membranes to materialize eco-friendly natural gas and biogas purification and hydrogen production.

Hollow porous carbon fiber and internal porous structure. Source | Toray

Toray innovated its new material by combining its polymer technology with its carbon fiber technologies, as well as with water treatment and other separation membrane technologies. Harnessing its polymer technology enabled the company to create a porous carbon fiber with uniformly continuous pores and carbon. Toray says it is possible to set nano- through micro-level pore sizes for porous structures, or to create a hollow fiber-shaped porous carbon fiber in the center of a fiber.

As R&D for this material continues, Toray plans to open its R&D Innovation Center for the Future next month. The new facility will serve as a global headquarters for strategic innovations by engaging with academic institutions and key partners from diverse fields. The company says it will collaborate with several partners in efforts leveraging its new material in a drive to commercialize more advanced gas separation membranes.

Under the Toray Group Sustainability Vision, the company looks to keep developing technologies that help materialize low-carbon economies by 2050 by contributing to resolutions of environmental, resources and energy issues.

Related Content

-

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

-

Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

-

Microwave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

.jpg;width=70;height=70;mode=crop)