Toray supplies HiCAM project with thermoset, thermoplastic prepreg technologies

Toray Composite Materials America and Toray Advanced Composites divisions support technologies reducing cost, improving performance and increasing delivery rates in airframe manufacturing.

Toray (Tokyo, Japan), a global company offering innovative technologies and advanced high-performance materials, is among the list of composite material suppliers that are members of the NASA Advanced Composites Consortium (ACC) and are supporting NASA’s (Washington, D.C., U.S.) Hi-Rate Composite Aircraft Manufacturing (HiCAM) project. The ACC is a public-private partnership which includes NASA, the Federal Aviation Administration (FAA), select aerospace and materials companies, and academia that supports the HiCAM project. The project seeks to dramatically improve the manufacturing rates of composite airframe structures for future single-aisle commercial aircraft manufactured in the U.S. Its approach includes the use of high-rate composite technologies to improve production rates and cost without sacrificing weight and performance attributes.

“The HiCAM project has completed tasks supporting formulation and is entering the next phase for technology development,” Richard Young, HiCAM project manager, says. “We are pleased to have Toray as one of the members representing raw material suppliers.”

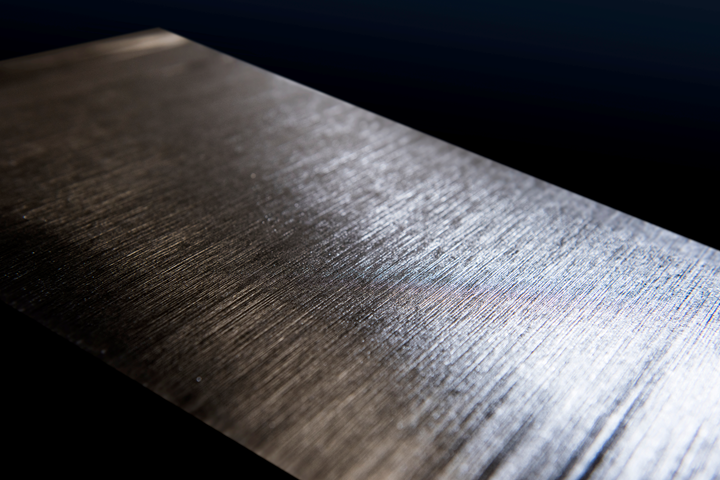

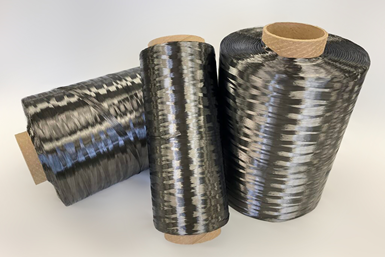

Toray Composite Materials America Inc. (TCMA, Tacoma, Wash., U.S.), manufacturer of Torayca carbon fiber and aerospace-grade thermoset prepregs, is involved in three sections of the project’s current phase supplying Torayca carbon fiber and next-generation thermoset prepregs. TCMA also provides process guidance of the materials’ use in automated fiber placement (AFP) process development, rapid cure and resin infusion for wing and fuselage structures. The thermoset prepregs use intermediate modulus plus (IM+) carbon fiber with a toughened epoxy resin system, reportedly providing structural performance, low resin content and tight physical property manufacturing tolerances.

According to Jeff Cross, TCMA director of business development for aerospace, “We’re proud to participate in the ACC’s effort to reduce cost, improve performance and increase delivery rates of single-aisle commercial aircraft to retain the United States’ competitive advantage in aircraft manufacturing.”

Toray Advanced Composites (TAC, Morgan Hill, Calif., U.S.), manufacturer of a broad range of thermoset and thermoplastic composite technologies, is directly involved in four additional sections of the program with a range of Cetex thermoplastic unidirectional (UD) tapes and material science input. These materials are said to represent state-of-the-art structural thermoplastic composites on standard, intermediate and IM+ Torayca carbon fibers and are being used in innovative part fabrication and assembly processes.

“Toray is honored to support this holistic material and process technology initiative,” Steve Cease, TAC VP of technology, includes, “helping U.S. aerospace manufacturing achieve an unprecedented four to six times production rate increase.”

Related Content

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.