Toyota Tundra composite seatback design awarded 2022 Altair Enlighten Award

BASF, Flex-N-Gate, L&L Products and Toyota limited an all-steel assembly, cutting 60 parts down to four composite pieces for 20% weight savings.

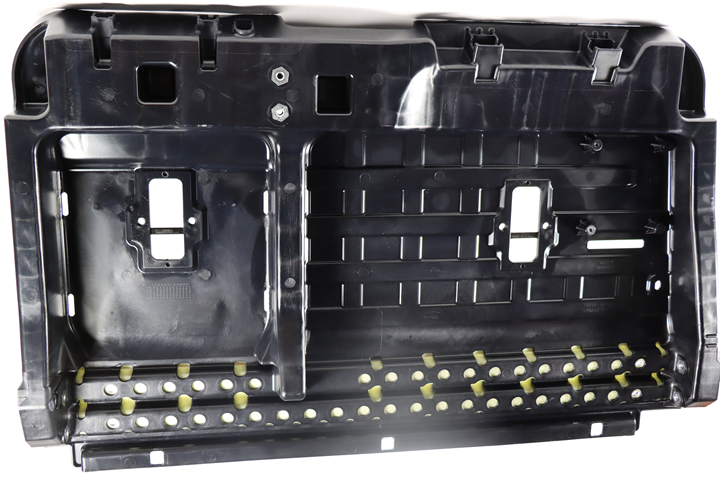

Toyota Tundra 2022 composite seatback. Photo Credit, all images: BASF, L&L Products, Flex-N-Gate, Toyota

BASF (Wyandotte, Mich., U.S.), Flex-N-Gate (Urbana, Ill., U.S.), Toyota (Plano, Texas, U.S.) and L&L Products (Romeo, Mich., U.S.) were awarded a 2022 Altair Enlighten Award for achievements in vehicle weight savings with the composite seatback design on the 2022 Toyota Tundra. This is the second time in three years that BASF, L&L Products and Toyota have been recognized in the module lightweighting category.

“Pultrusion composite technology allowed us to design a seat structure that was 20% lighter compared to the previous model and to meet our cost goals,” Vik Bhatia, group manager for Engineering Design Chassis at Toyota, says. “BASF, L&L Products and Flex-N-Gate were great partners that help us reach our targets.”

The seat structure is said to be the first interior application for L&L Products’ Continuous Composite Systems (CCS) technology that uses BASF’s polyurethane pultrusion system Elastocoat 74850. CCS is a fiber-reinforced composite carrier with highly engineered sealants and adhesives in a two-dimensional profile. In this application it was overmolded with BASF’s impact-modified polyamide 6 (PA6) Ultramid B3ZG7 CR to create the 3D shape of the 60% seatback.

“With this partnership, we were able to eliminate an all-steel assembly which contained 60 stamped and welded parts and integrate into four composite parts which reduced assembly and scrap costs associated with the metal seat structure,” Hank Richardson, product engineering manager, L&L Products, adds. “This also allowed for greater functionality of the seating system.”

“We continue to show how pultrusion can deliver lightweight, cost-effective solutions as well as integrated functionality,” Kipp Grumm, technology leader for Thermoplastic Composites, Performance Materials, BASF Corp., concludes. “The unique design of the injection overmolded pultruded beam in the seat structure also passed all relevant crash test requirements and opens the door for more adoption of composites in automotive applications.”

Related Content

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.