TPRC training courses target thermoplastic composites

Three upcoming in-person thermoplastic composites courses, ranging from entry-level to advanced, are organized to enhance composites professionals’ knowledge in this burgeoning field.

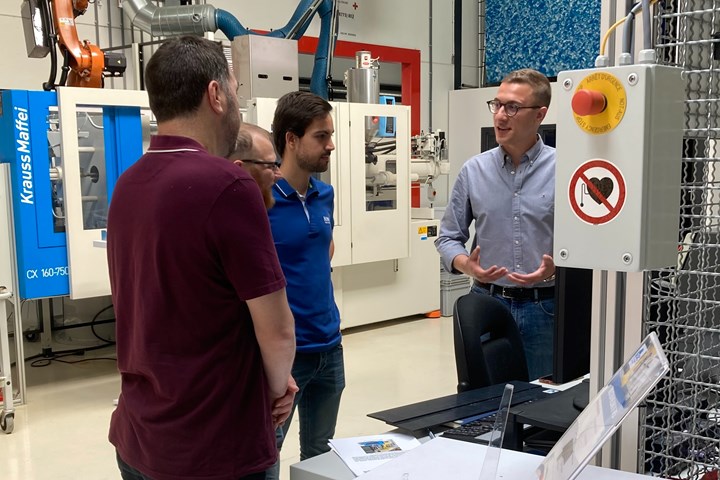

TPRC leverages its state-of-the-art lab facilities and the support of its academic partners to provide thermoplastic composites training and education. Photo Credit, all images: TPRC

Thermoplastic composites are still fairly niche. Because of this, the ThermoPlastic composites Research Center (TPRC, Enschede, Netherlands) has found it important to share its own wealth of experience and acquired knowledge on the topic through a range of training courses, including upcoming ones like “Introduction to Thermoplastic Composites,” “Joining of Thermoplastic Composites” and “Advanced Forming of Thermoplastic Composites.” All of TPRC’s courses are under constant development and have each helped hundreds of composites professionals get to the next level.

“Thermoplastic composite materials can be used in the construction of lighter airplanes,” Sebastiaan Wijskamp, technical director of TPRC, explains. Wijskamp is actively involved in the courses. “Only a limited number of experts worldwide focuses on the development and application of thermoplastic composites. Don’t underestimate how small and specialized, and how future-oriented, our field is. You can’t divide this kind of responsibility among a small group of specialists. Everyone would benefit from our market growing.”

What does TPRC’s course range look like at the moment and how has it developed over the years? “In 2014 we started with an introductory course on thermoplastic composites. At the time, we saw that both our partners and non-members really wanted to increase their basic knowledge,” Wijskamp continues. “So the course dealt with questions such as: What are thermoplastic composites? How can they be applied? What kind of materials are available? The course was primarily based on the knowledge present at the University of Twente [UT, Enschede, Netherlands], one of the founders of TPRC. Wouter Grouve — who used to be a researcher at TPRC and now works for UT — and I developed it together. Early on we noticed that people often wanted to know more, for example about press forming. We therefore decided to set up an advanced forming course, based on specialist information from our PhD candidates’ theses. The practical part of all our courses is taught in our lab by our own researchers.”

TPRC currently offers three courses (below) to its partners and external companies. Tailor-made courses are also available upon request. TPRC says its partners are key to developing its course range.

“Introduction to Thermoplastic Composites,” available in spring 2023, features and explains the basics of thermoplastic composites. Participants are introduced to processing technologies during hands-on lab work involving consolidation techniques, press forming, laser-assisted tape placement, welding, mechanical testing and nondestructive testing (NDT). The two-day course, which takes place in the lecture room and lab facility of TPRC, aims at entry-level participants.

The two-day “Joining of Thermoplastic Composites,” course, taught in collaboration with KVE Composites (The Hague, Netherlands), is available this December 2022. Geared toward advanced-level participants, it offers knowledge on the different joining techniques available for thermoplastic composites, with a focus on welding methods. The course consists of theoretical and practical sessions, which elaborate on the following topics:

- Mechanisms underlying fusion bonding.

- Potential and challenges of different welding techniques.

- The adhesion of thermoplastic composites to dissimilar materials.

- Correlation between process parameters and joint quality.

In “Advanced Forming of Thermoplastic Composites,” available starting in spring 2023, advanced-level participants will learn the ins and outs of press-forming thermoplastic composites. Over the course of two days, the classroom sessions and practical lab exercises elaborate on the following topics:

- Process parameter selection based on material properties.

- Effects of tool design on manufacturability and part quality.

- Influence of blank handling systems on formability.

- The cause of process-induced defects.

- The use of predictive process simulation tools.

This course is organized with AniForm Engineering, a TPRC spinoff company.

Who would benefit from taking a course at TPRC? “The introductory course is fairly broad, which is why we get a lot of engineers who are used to working with thermosets or metals, but not yet with thermoplastic composites,” Wijskamp explains. “Then there are engineers who do have some experience and come to refresh their knowledge, as well as salespeople and business developers wanting to learn more about thermoplastic composites. The course has a low threshold and is also open to companies who aren’t TPRC members. It allows them to get to know us informally and learn more about the field. The groups are often small, with lots of interaction. Suppliers and customers mingle freely during course days. The advanced forming course is more geared toward engineers who, for instance, want to press-form thermoplastic composites.”

Wijskamp explains what the atmosphere is like during course days. “We receive our guests at the TPRC lab,” he says. “The atmosphere is open and informal. We eat a nice lunch together and in the evening we go out to dinner in the city center, to get to know each other even better. Course participants hail from all over the world. They often work in labs, also in other sectors like the wind industry. This makes the groups very diverse and that’s good for the atmosphere. Our people also really enjoy contributing to the courses. Take our PhD candidates. They are generally very focused on their own specialist research, and touching base with the professional field in the context of a course reminds them of the bigger picture. The whole team is involved and that feels very special.”

Upcoming courses

At the end of 2022, TPRC is launching a new welding course, which will cover the basic principles and different methods of welding thermoplastic composites.

“We use two welding methods in our own lab: induction welding and resistance welding,” Wijskamp says. “This allows us to compare welded joints to both adhesive bonds and conventional ways of bonding, such as the use of rivets. All in all, welding is the modern-day holy grail in our field. A decade ago, only small thermoplastic composite parts were used in aviation. Now the industry is investigating how to make big and complex parts out of thermoplastics. One way is to weld together different elements. In the end it’s up to our partners to apply our knowledge; they’re the ones involved with industrialization.”

“Anyone can find information online and turn it into a course, but we do much more than that,” Wijskamp adds. “Teaching is an art in itself and it’s great to collaborate with professionals from our field. In our courses, everyone is really motivated to work with thermoplastic composites and they fully immerse themselves for two days, which keeps me on my toes as well. Course participants often give me new insights and feedback that help us continually improve our courses.”

For more information about TPRC’s courses and how to join, visit tprc.nl/training

Related Content

Submit abstract to speak at CW Bonding and Welding Tech Days in April

Online event in spring 2025 will feature six presentations exploring reliable methods for the assembly and joining of composite components. Abstract deadline is Feb. 3, 2025.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreDeveloping repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More