Trex Company, CNG announce top U.S. schools for annual recycling challenge

Composite decking manufacturer and specialty polyethylene film producer reward students for actively engaging in upcycling program.

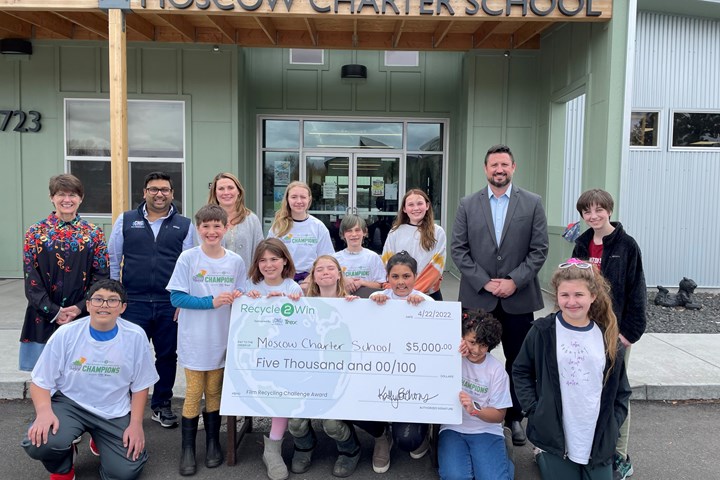

Photo Credit: Moscow Charter School

Trex Co. (Winchester, Va., U.S.), a manufacturer of high-performance, low-maintenance composite decking and outdoor living products, recently concluded its 15th annual Trex Plastic Film Recycling Challenge and is pleased to announce and reward the winners.

The nationwide challenge kicks off each fall on America Recycles Day (Nov. 15) and concludes the next spring on Earth Day (April 22). This year, over the course of five months, students in grades K-12 worked together to collect and recycle the most polyethylene plastic film for the chance to win high-performance Trex products to beautify their campuses. For the first time, students involved in the latest challenge also competed for the chance to win cash prizes for their schools, thanks to corporate sponsor Charter Next Generation (CNG, Milton, Wis., U.S.), a leading provider of specialty polyethylene films in North America.

“For the past 15 years, the Trex Plastic Film Recycling Challenge has provided thousands of students a hands-on opportunity to make a difference in their communities and schools by learning the value of recycling,” Stephanie Hicks, materials sourcing manager for Trex Co., says. “Paired with CNG’s generous corporate sponsorship, we continue to broaden adoption of our easy-to-implement annual recycling program among schools and in turn, increase the overall amount of plastic film material upcycled into Trex’s composite decking.”

Coming out on top in the 2021-2022 challenge was Moscow Charter School (Moscow, Idaho, U.S.), where students collected 7,735 pounds of recycled plastic film.

Started in 2007, the Trex Plastic Film Recycling Challenge was conceived to educate students about upcycling and actively engage them in the recycling of plastic film, a key ingredient in the company’s eco-friendly composite decking, which is made from 95% recycled and reclaimed materials. Students from 686 schools participated in the 2021-2022 challenge. Together, they collected a combined total of 323,586 pounds of polyethylene plastic film, contributing to the nearly 400 million pounds of plastic film that Trex diverts from landfills annually.

Trex awards prizes to the top recyclers based on grade level, school size and region. Fifty-seven regional winners were recognized this year, representing schools from across the country. Coming out on top in the 2021-2022 challenge was Moscow Charter School (Moscow, Idaho, U.S.), where students collected 7,735 pounds of recycled plastic film through classroom challenges and community-wide outreach.

New to this year’s program, CNG’s sponsorship funds further incentivized the overall first and second place elementary, middle and high schools that recycled the most polyethylene plastic film during the collection period. CNG is proud to present $5,000 each to the top recyclers at Moscow Charter School, E.L. Wright Middle School (Columbia, S.C., U.S.) and North Cross High School (Roanoke, Va., U.S.). Prizes of $2,500 each go to the second-place winners at each level, including Woodland Elementary School (Monroe Township, N.J., U.S.), Einstein Middle School (Appleton, Wis., U.S.) and York Community High School (Elmhurst, Ill., U.S.).

Additionally, a special award of $2,500 goes to the students at Maple Grove Elementary School (Greenfield, Wis., U.S.( in recognition of their creativity and impressive activity on social media. Through teamwork, grassroots community outreach and outstanding use of social media, this school educated and engaged its community to get involved in the recycling program and generated a steady stream of images, videos and posts using the #TrexRecyclingChallenge and #Recycle2Win hashtags. In addition to the cash prizes, CNG developed and managed a landing page, Recycle2Win.com, which showcased a leaderboard, social media activity and competition news.

“CNG has been thrilled with the energy, engagement and excitement students brought to this year’s competition and wants to thank every school around the country for their participation,” Kathy Bolhous, chief executive officer (CEO) of Charter Next Generation, says. “We also want to thank Trex for the opportunity to partner on this year’s competition and hope to build on what was started this year, for years to come.”

CNG has a high focus on diverting plastic film from landfills by developing materials that are readily recyclable and actively promoting the importance of recycling. The company is a long-time participant in the NexTrex Recycling Program and worked closely with Trex on its GreenArrow platform of sustainable films for flexible packaging to ensure their suitability for the Trex recycling stream.

Said to be one of the largest recyclers of plastic film in North America, Trex produces its decking using 95% recycled and reclaimed materials, including a mix of wood scrap and polyethylene plastic film ranging from a variety of common household items such as grocery bags, newspaper sleeves and bubble wrap, to retail plastic waste including pallet wrap and industrial packaging. Each year, Trex manufacturing diverts nearly 400 million pounds of plastic waste otherwise destined for incineration or landfills.

The 16th Annual Trex Plastic Film Recycling Challenge will kick off on November 15, 2022. Interested schools can sign up by completing a brief form on Recycle.Trex.com. Once enrolled, Trex makes participation easy by supplying each school with a turnkey toolkit, including detailed instructions, promotional materials, recycling bins and a list of qualifying recyclable materials. Schools can also leverage the easy-to-navigate Trex recycling website that features engaging content and educational resources.

Related Content

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

Athletic shoe developed with repurposed thermoplastic waste

Manufactured via a single-step molding process, Decathlon’s Traxium Compressor soccer cleats propel the sporting goods market toward more recyclable solutions.

Read MorePrecision pyrolysis: Controlled, heat-based composites recycling for higher material properties

Japan-based Fuji Design’s recycling technology involves controlled, cyclical heating and cooling for higher-performance fiber reclamation. New partnership with Teijin Ltd. aims to scale up and commercialize the technology.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More