Viable routes to recycling wind turbine blades found in NCC’s sustainable wind research program

Launched SusWIND program aims to establish a viable circular supply chain to tackle the main challenges of legacy and future composite blades in the U.K.

The National Composites Centre (NCC, Bristol, U.K.), in partnership with the Offshore Renewable Energy (ORE, Glasgow, U.K.) Catapult, has launched the SusWIND program to drive the future sustainability of composite wind turbine components. In its first annual review, the NCC has published the key findings of the program and sets out ambitious plans to tackle the main challenges of legacy and future blades.

The review highlights a number of key achievements that are critical to a sustainable future of wind turbine blades, including:

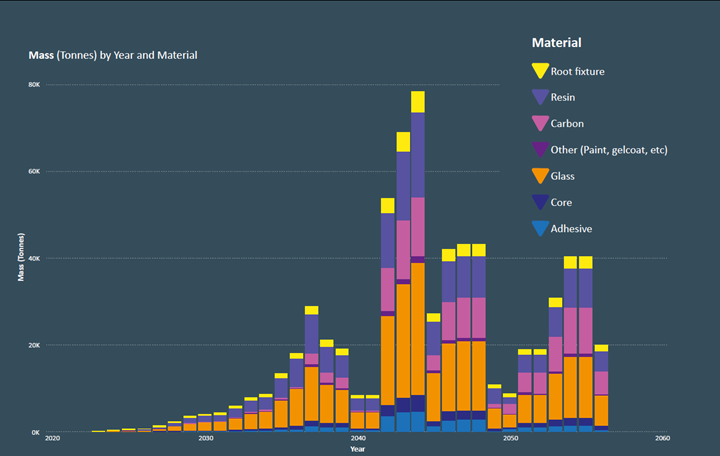

- A full decommissioning profile of all U.K. blades has been developed, forecasting composite waste streams for the next 30 years and enabling partners to make key decisions at blade end of life (EOL).

- Mechanical recycling and cement kiln co-processing have been identified as the only viable industrial scale processing routes for glass fiber composite waste for the coming decade.

- Development requirements of promising low technology readiness level (TRL) processing routes have been defined, for EOL blade waste to deliver more benefit for the higher volumes of waste post-2032.

- A cradle-to-grave lifecycle assessment has identified where targeted introduction of alternative materials in manufacturing can reduce the environmental impact of the blade.

- Welcomed important industry partners to collaborate in the program, including Vestas (Aarhus, Denmark), SSE Renewables (Perth, U.K.), EDF Renewables (France), Shell (London, U.K.) Net Zero Technology Centre (Aberdeen, Scotland), The Crown Estate (London), RenewableUK (London), BVG Associates (Swindon, U.K.) and Zero Waste Scotland (Stirling, Scotland).

“Developing a circular supply chain for wind turbine blades is the ultimate goal for the SusWIND program,” Phil Slack, head of energy at the NCC, points out. “Our review of the first year highlights the significant progress we have made towards that goal. Our ambition is to end 2022 with a meaningful investment case for critical industrial capabilities in mechanical recycling and cement kiln co-processing of glass fiber-reinforced composites in the U.K.”

Fig. 2. How SusWIND is delivering insight to the industry. Photo Credit: NCC SusWIND annual review, April 2022.

The SusWIND program is a leading program in the NCC effort to establish a viable circular supply chain for all composites and all industries in the U.K. SusWind is calling for support and participation from across the full range of industrial sectors to grow a community of stakeholders. Further investment and collaboration will help the program to create EOL value from past and current generations of turbine blades and share those learnings with other sectors to embed circularity at the heart of future generations of composite components.

Find the annual review here.

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.