Vineyard Wind I offshore wind project poised for finalization

Bureau of Ocean Energy Management completes environmental analysis for proposed U.S. commercial-scale offshore wind farm with expectations to announce a decision by mid-2021.

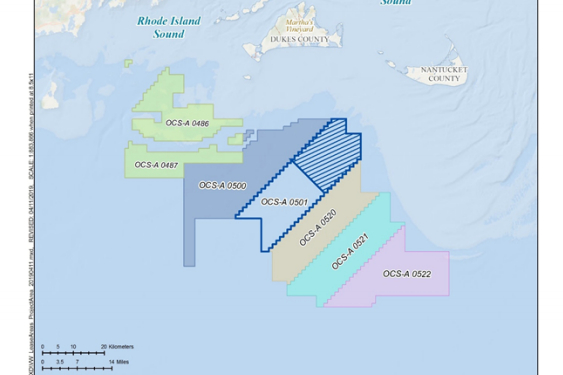

The Vineyard Wind map indicates the Vineyard Wind lease area (OSC-A-0501), Bay State wind lease area (OSC-A-0500), Deeper Wind lease area (OSC-A-0486-7), Equinor Wind U.S. lease area (OSC-A-0520), Vineyard Wind (Liberty Wind) lease area (OSC-A-0522) and Mayflower Wind Energy lease area (OSC-A-0521). Photo Credit: BOEM

The Department of the Interior (Washington, D.C., U.S.) announced on March 8 that the Bureau of Ocean Energy Management (BOEM) has completed the environmental analysis of the proposed Vineyard Wind I offshore wind project. This is said to represent major progress in the Biden-Harris administration’s goal to accelerate responsible development of renewable energy on public lands and waters as a key component of tackling the climate crisis and creating jobs.

“The United States is poised to become a global clean energy leader,” says Principal Deputy Assistant Secretary - Land and Minerals Management Laura Daniel Davis. “To realize the full environmental and economic benefits of offshore wind, we must work together to ensure all potential development is advanced with robust stakeholder outreach and scientific integrity.”

Located 15 miles off the coast of Martha’s Vineyard, an island in Dukes County, Massachusetts, Vineyard Wind 1 is slated to become the first commercial-scale offshore wind farm in the United States if the project is approved. With a generating capacity of 800 megawatts (MW), the project will reportedly provide significant benefits to the Commonwealth of Massachusetts by providing clean electricity to power more than 400,000 homes, creating thousands of good paying jobs and reducing electricity rates by $1.4 billion over the first 20 years of operation. The project is also expected to reduce carbon dioxide emissions by 1.68 million metric tons annually, the equivalent of taking 325,000 cars off the road each year.

“Offshore energy development provides an opportunity for us to work with Tribal nations, communities and other ocean users to ensure all decisions are transparent and utilize the best available science,” says BOEM Director Amanda Lefton. “We appreciate everyone’s participation in the process and look forward to continuing to work with stakeholders on the future analysis of offshore wind projects.”

The origins for the Vineyard Wind 1 Project date back to 2009, when the Commonwealth of Massachusetts and BOEM began a stakeholder process to identify offshore wind energy areas south of Martha’s Vineyard. Following that process, Vineyard Wind was awarded a lease area in a competitive auction held by BOEM in 2015, submitted its state and federal permit applications in 2017 and subsequently won the first large-scale offshore wind contract in a competitive procurement in Massachusetts in 2018.

The Vineyard Wind 1 project has already received all relevant permits required by the Commonwealth of Massachusetts as well as regional and local bodies. Vineyard Wind is proud to have community partnerships and agreements with Vineyard Power on Martha’s Vineyard, the towns of Barnstable and Nantucket, fishery mitigation agreements with the states of Massachusetts and Rhode Island, a fishery science collaboration with UMass Dartmouth’s School of Marine Science and Technology, as well as a landmark agreement with leading environmental organizations on protection of the North Atlantic Right Whale. Vineyard Wind has also committed to using the New Bedford Marine Commerce Terminal during construction of the project.

Vineyard Wind is expected to reach financial close in the second half of 2021 and begin delivering clean energy to Massachusetts in 2023.

“We want to thank BOEM for all of the work they’ve done since we submitted the permit application in December of 2017 on this first-in-the-nation project,” says Vineyard Wind CEO Lars T. Pedersen. “More than three years of federal review and public comment is nearing its conclusion and 2021 is poised to be a momentous year for our project and the broader offshore wind industry. Offshore wind is a historic opportunity to build a new industry that will lead to the creation of thousands of jobs, reduce electricity rates for consumers and contribute significantly to limiting the impacts of climate change. We look forward to reaching the final step in the federal permitting process and being able to launch an industry that has such tremendous potential for economic development in communities up and down the Eastern seaboard.”

Later this week, BOEM will publish a Notice of Availability for the Final Environmental Impact Statement (EIS) in the Federal Register, which analyzes the potential environmental impacts of making a decision on Vineyard Wind’s Construction and Operation Plan.

On June 12, 2020, as a result of comments received during the National Environmental Policy Act process and in coordination with cooperating agencies, the Draft EIS was supplemented with additional analysis. Additional areas of analysis included reasonably foreseeable effects from an expanded cumulative activities scenario for offshore wind development, previously unavailable fishing data, a new transit lane alternative and changes since publication of the Draft EIS to the proposed project.

Following a 45-day comment period and five virtual public meetings, BOEM incorporated comments received on the Draft EIS and the supplemental analysis into the Final EIS.

BOEM is working with the appropriate parties to finalize the Section 106 process, consistent with the National Historic Preservation Act, and to issue a record of decision whether to approve, disapprove or approve with modifications the proposed project.

The U.S. Army Corps of Engineers and the National Marine Fisheries Service will sign this joint record of decision for their respective authorization decisions. The Final Environment Impact Statement is available here.

Related Content

NCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

Read MorePolar Technology develops innovative solutions for hydrogen storage

Conformable “Hydrogen in a Box” prototype for compressed gas storage has been tested to 350 and 700 bar, liquid hydrogen storage is being evaluated.

Read MoreAchieving composites innovation through collaboration

Stephen Heinz, vice president of R&I for Syensqo delivered an inspirational keynote at SAMPE 2024, highlighting the significant role of composite materials in emerging technologies and encouraging broader collaboration within the manufacturing community.

Read MoreCollins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreRead Next

Orbital Composites to demonstrate containerized 3D printing robots for AM wind blade manufacture

Project aims to demonstrate additive manufacturing of >100-meter-long composite wind blades with >25% reduced cost.

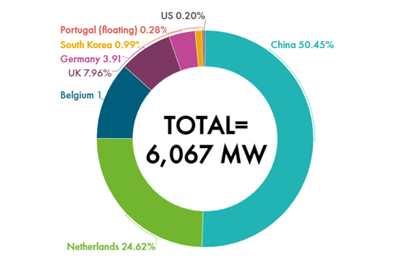

Read MoreGWEC data reports 2020 as second-best year for global offshore wind sector

Despite the impact of COVID-19, 2020 marks 6 GW of additional capacity for a total of 35 GW, with steady growth in China, Europe and the U.S.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More