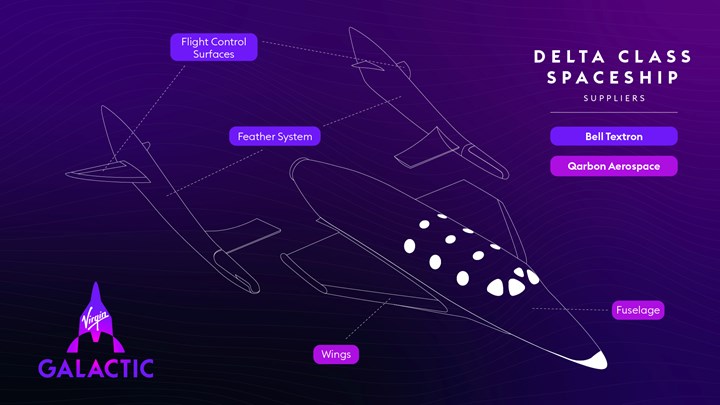

Virgin Galactic announces primary suppliers for Delta class spaceships

Bell Textron Inc. and Qarbon Aerospace are slated to manufacture major subassemblies — flight control surfaces, complex composite components and more — for the next-gen spaceships.

Virgin Galactic Holdings Inc. (Mojave, Calif., U.S.), an aerospace and space travel company, has reached an agreement with Bell Textron Inc. (Fort Worth, Texas, U.S.) and Qarbon Aerospace (Red Oak, Texas, U.S.) to manufacture key subassemblies for the company’s new Delta class spaceships. The production-model vehicle is designed to fly weekly with six passengers per ship. Production is slated to begin in 2023.

Bell, a subsidiary of Textron Inc. (Providence, R.I., U.S.) with more than 85 years of manufacturing experience in the aviation industry, including vertical lift and space technology will supply the feathering system and flight control surfaces. Qarbon Aerospace, known for its expertise in constructing large, complex composite parts for aerospace and aviation (see CW’s recent tour), will produce the fuselage and wing. The companies were selected following a competitive request for proposal (RFP) process based on the ability to meet Virgin Galactic’s unique design and fabrication requirements.

Virgin Galactic will continue to be responsible for the overall system architecture, design authority for all components, and the final assembly, integration, checkout and acceptance testing of the vehicles.

“The Delta class spaceships are an evolution of our distinctive flight system, designed for improved manufacturability, maintenance and flight rate capability,” Virgin Galactic CEO Michael Colglazier explains. “Bell and Qarbon Aerospace are established partners who bring know-how, ideas and resources that will enable us to produce up to six new Delta Class ships per year. Together with Aurora Flight Sciences, who is producing our next gen motherships, we now have the primary suppliers in place to propel the production of our spaceline fleet at scale.”

As previously announced, the spaceships will be assembled at Virgin Galactic’s new facility in Arizona. The first Delta class spaceships are expected to commence revenue-generating payload flights in late 2025, progressing to private astronaut flights in 2026.

“The Delta spaceship manufacturing process will benefit from our investment in digital twin technology, which enables seamless integration, real-time collaboration, strong governance and increased production efficiency and reliability,” Swami Iyer, Virgin Galactic president, aerospace systems, adds.

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Next-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.