XlynX Materials releases new polymer molecular glue: BondLynx

"Hyper glue" adhesive forges new bonds at the molecular level to permanently adhere difficult-to-bond polymers.

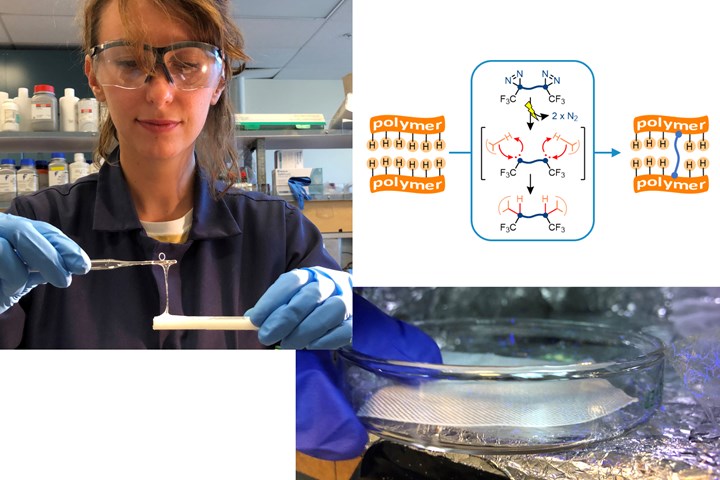

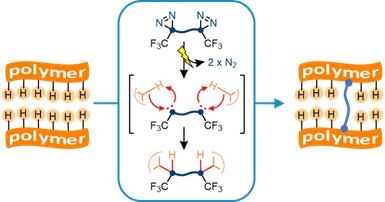

BondLynx employs bis-diazirine chemistry to create covalent chemical bonds between polymer chains, permanently crosslinking them together through strong carbon-carbon bonds. BondLynx molecular glues can also be applied to polymer textiles to link and strengthen the fibers. Photo Credit: XlynX Materials

XlynX Materials (Victoria, B.C., Canada) has announced the creation of a new class of adhesives they are calling “molecular glues.” These make it possible to permanently adhere difficult-to-bond polymers such as polyethylene and polypropylene to themselves, and to other materials, through exceptionally strong chemical bonds.

BondLynx creates covalent chemical bonds between polymer chains, permanently crosslinking them together through strong carbon-carbon bonds — the same type of joinery found between carbon atoms in the polymer chains themselves. Photo Credit: XlynX Materials

Conventional adhesives typically take advantage of mechanical forces to hold materials together. BondLynx employs bis-diazirine chemistry to create covalent chemical bonds between polymer chains, permanently crosslinking them together through strong carbon-carbon bonds — the same type of joinery found between carbon atoms in the polymer chains themselves. Once BondLynx has been applied to a polymer, the crosslinking process can be initiated by heat, ultraviolet (UV)/visible light or an electric field, depending on the specific demands of the manufacturing process.

"What's really amazing about BondLynx is that it can ‘glue’ virtually any plastic to any other plastic,” says Jeremy Wulff, professor of Organic Chemistry at the University of Victoria. “BondLynx acts by inserting itself into the carbon-hydrogen bonds that are present in almost every commodity polymer. The potential applications are limitless."

BondLynx has undergone adhesive testing on a wide range of polymer and polymer-metal combinations. Remarkably, even elastomers and damp surfaces can be bonded with BondLynx, opening broad opportunities for novel applications, for example, in the medical field.

Strengthening of fabrics

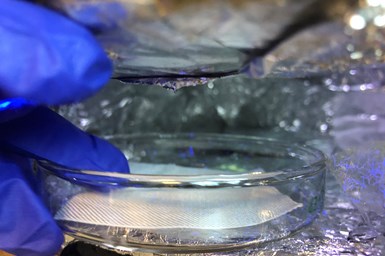

Application of BondLynx molecular glue to strengthen fabric. Photo Credit: XlynX Materials

In addition to being used directly as polymeric adhesives, BondLynx molecular glues can be applied to polymer textiles to link and strengthen the fibers. It has proven effective in strengthening ultra-high molecular weight polyethylene (UHMWPE) fabrics for ballistics protective equipment and wind sport applications.

“As a leading manufacturer of body armor products, PRE Labs had a privilege to test and use ultra-high performance fabrics crosslinked with BondLynx,” explains PRE Labs CEO Brad Field. “Our evaluations to date have confirmed that these new-generation cross-linking agents can significantly enhance the tear and perforation resistance along with mechanical properties of high-performance fabrics.” Researchers at the University of British Columbia, University of Alberta, McGill University and industry labs have already begun similar testing.

Further information

Samples for testing and research purposes are now available from XlynX Materials. Please send your request to info@xlynxmaterials.com. For a deeper look at the science behind this new technology, see: “A broadly applicable cross-linker for aliphatic polymers containing C–H bonds” in Science and “Flexible polyfluorinated bis-diazirines as molecular adhesives” in Chemical Science.

About BondLynx

BondLynx is a revolutionary new type of adhesive that takes advantage of chemical crosslinking to form ultra-strong covalent bonds between a wide range of “impossible to bond” polymers and other materials.

About XlynX Materials Inc.

XlynX (pronounced “ex-links”) is a rapidly-emerging specialty chemical company focusing on the development of novel diazirine-based crosslinking molecules, carbon materials, and the combination of both technologies to provide solutions to the world’s toughest composite materials challenges. Located on Canada’s west coast, XlynX’s team of chemists and physicists is committed to working with researchers around the world to bring new and exciting chemical products to market. XlynX Materials gratefully acknowledges the financial support of the Mitacs Accelerate program.

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More