At JEC Europe 2015: Airtech International

This Huntington Beach, CA, US-based supply house emphasized its Wrightlease 2 fluoropolymer pressure-sensitive tape, Airdraw bagging film, TB-G48 Carbon Tooling Boards and announced a US expansion.

At JEC Europe 2015, Aitech International (Huntington Beach, CA, US) promoted several of its premiere products:

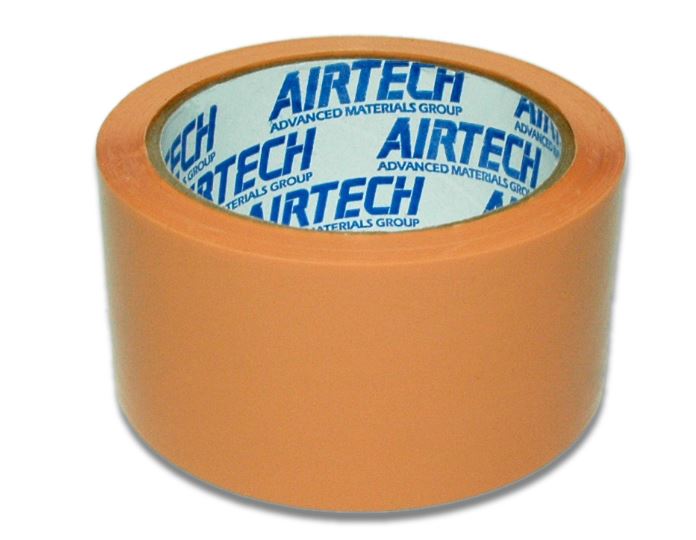

Wrightlease 2 is Airtech's newest pressure-sensitive tape for multi-purpose use in the manufacture of composite parts. An extruded fluoropolymer film coated with silicone pressure-sensitive adhesive, its orange color is highly visible, helping technicians to reduce time stripping after use and avoid incomplete removal. Wrightlease reprotedly has a high elongation and tensile strength so it can be applied wrinkle-free over complex shaped parts. Benefits are said to include

- excellent release from all common resin systems, which means it can be used for semipermanent release applications.

- good adhesion to metal, composite, tooling block and rubber tooling, making it a good choice for multiple applications in the workshop.

- high elongation, which allows easier covering of complex contour surfaces.

Also available is Airdraw 2 vacuum-bagging film, available in widths to 356 cm, is embossed with a ''cracked ice'' pattern which allows for rapid air removal when placed under vacuum. The film has been formulated for increased stiffness to assist in maintaining a breathable pattern. Airtech says Airdraw 2 is not affected by environmental conditions and will not soften in high humidity, thus enabling superior breathability. It is designed primarily for ply compaction with the added benefit of not requiring a breather. It is embossed from one side of the film — under close examination the film has a flat side and a raised side. The outer surface of the roll is the raised side. For best results, the user is advised to place the raised side against the part surface on top of a perforated release film. Benefits include

- a embossed pattern that provides a network of air passageways, eliminating need for separate layer of breather.

- an improved stiffer formulation that keeps the air path open, resulting in hgiher vacuum levels, faster.

- wide width potential that makes compacting large parts even faster with no seams required.

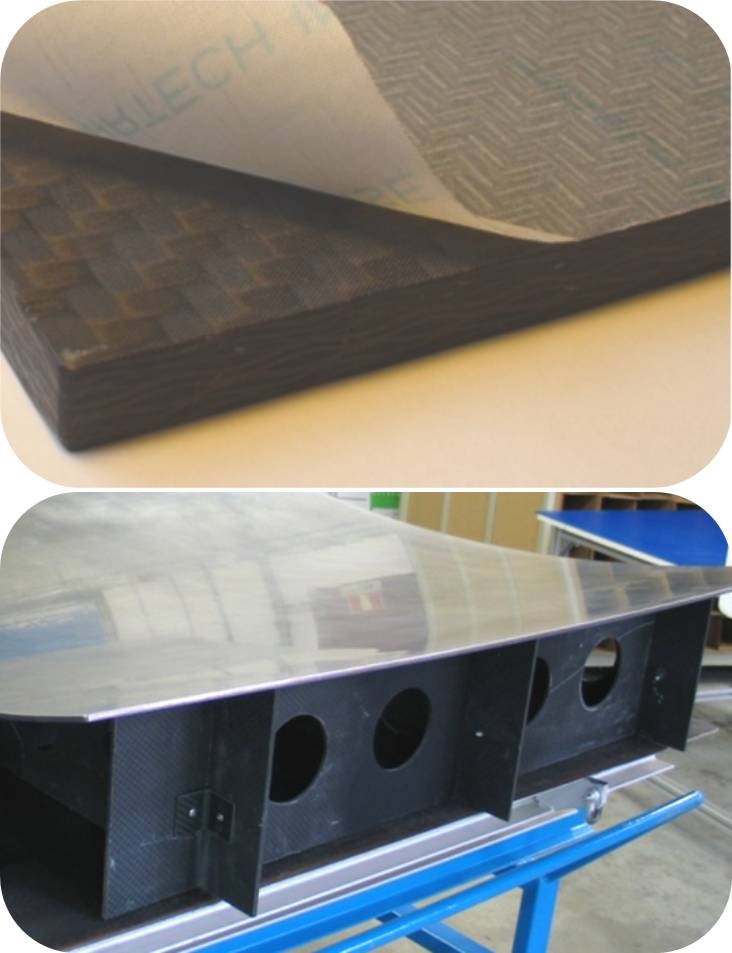

Also in the spotlight, Airtech's TB-G48 Carbon Tooling boards, can be used to build composite mold tool support structures, bonding jigs, drill fixtures, post-cure braces and many more stable tooling pieces. Airtech says it employs the very latest in resin and manufacturing technology to produce its low-cost and performance-optimized carbon tooling boards. Benefits include the following:

- A high glass transition temperature (247°C), which delivers stability at high temperature, ensuring long tool life and reducing lifecycle costs.

- A highly visible peel ply layer in place on both sides of the panel, providing surface protection during storage and machining. Removal of the peel ply leaves a textured surface for bond preparation.

- In addition to the standard board sizes, TB-G48 also can be supplied custom manufactured in thick section, ideal for when boards need to be machined to profile for bonding jigs.

- Laminate constructions can be optimized for cost or performance by selecting fabric styles and orientations.

Finally, in September 2014, Airtech invested in an 11,300m2 facility in Springfield, TN, US, which will become the new home for its Custom Engineered Products Div. It will be located at 210 Evergreen Dr., in the North Springfield Industrial Park.

Related Content

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More