Automated measurement instruments for fiber, filament testing

CAMX 2023: Dia-Stron presents fibra.auto, a new, customizable reference platform for automated sample handling and the LEX/IFSS interfacial shear module.

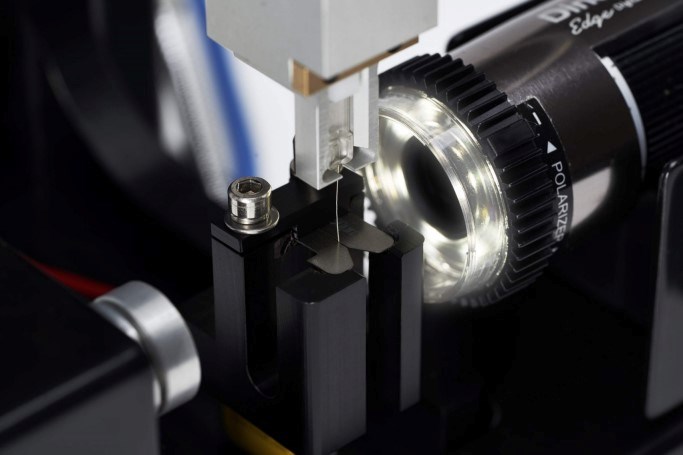

LEX/IFSS module up close. Photo Credit, all images: Dia-Stron

Dia-Stron Inc. (Clarksburg, N.J., U.S.) is a manufacturer of testing instruments for fibers and filaments, specializing in ultralow force testing of fibers, automation and sample mounting methods. Dia-Stron will be showcasing the new fibra.auto automated platform, alongside its LEX/IFSS micro-bond instrument.

The LEX/interfacial shear strength (LEX/IFSS) module provides interfacial shear data on the debonding force of microdroplets on single fibers and filaments. The system features a camera and light source that enable users to visualize the fiber and droplet during the test. Users can also record the mode of failure with video and image capture. The micro-bond method can be applied to a wide variety of fibers and matrices and is said to present a strong alternative to pull-out and fragmentation testing. The method can be applied to a number of fiber and filament types including glass, carbon, ceramic, aramid, basalt or natural fibers.

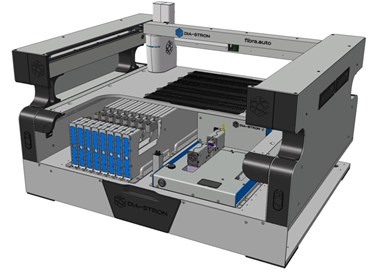

Fibra.auto is Dia-Stron’s latest leap forward in automated sample handling and multi-measurement workflows. Fibra.auto is a customizable platform to which fiber dimensional, tensile and cyclic fatigue testing modules can be added. It runs entirely through the company’s intuitive, user-focused software, fibra.

Fibra.auto diagram.

At the heart of fibra.auto is a proprietary and patent-pending cartesian (three-axis) coordinate robot that can accurately and reliably pick and place samples, maximizing reach within its internal dimensions without the need for compressed air. Up to five cassettes of prepared fiber samples can be loaded on the platform, enabling users to run 250 specimens without user intervention. According to Dia-Stron, automated workflows have numerous benefits, including maximized testing throughput, improved data quality, consistent specimen integrity and improved safety/ergonomics.

Fibra.auto is designed to fit inside an environmental chamber, allowing for relative humidity and temperature control during testing. This provides consistency and the ability to study the effects of different environmental conditions on the mechanical behavior of fibers.

Related Content

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

-

Nine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

-

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.