CAMX 2016 preview: AGFM

American GFM Corp./GFM (AGFM, Chesapeake, VA, US; GFM, Styer, Austria) is introducing its Model US-120/CM-10 system, featuring automated and semi-automated ply cutting, sequential offloading, sorting and kitting to prepare for ply lay up.

American GFM Corp./GFM (AGFM, Chesapeake, VA, US; GFM, Styer, Austria) is introducing its Model US-120/CM-10 system, featuring automated and semi-automated ply cutting, sequential offloading, sorting and kitting to prepare for ply lay up. These tasks have typically been performed manually, and have involved non-computer-supported processes, other than automated computerized nesting of individual plies. Model US120-CM10 features a three-zone ply cutter, which provides maximum throughput by enabling ply marking, ply cutting and ply offloading simultaneously, thereby enabling the operator to be consistently productive, offloading while both the marking and cutting of additional plies are being performed simultaneously by separate gantries in separate zones along the length of the machine. The cutting gantry is driven by a linear motor drive system. This provides ultrasonic ply cutting at a maximum of 4,800 inches/minute, with acceleration rate of 10-15 m/sec2, vs. 1.5 m/sec2 for other models. AGFM says the production output of the US-120/CM-10 is more than twice that of the other ply cutters.

NEW CULTURE ENABLING HIGH PRODUCTION SEQUENTIAL PLY OFFLOADING, SORTING AND KITTING FOR LAYUP

AGFM/GFM have developed a new computer supported system called Pick & Distribute (P&D), that addresses and eliminates the problems mentioned above, that are part of the Traditional Culture involving ply offloading, sorting and kitting.

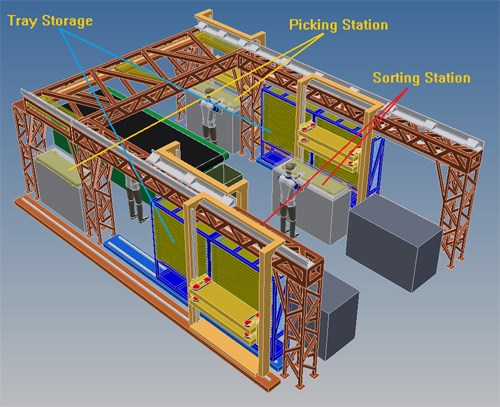

Complete American GFM Pick and Distribute System

The system starts with an operator on each side of the machine offloading the plies from a given window (area on the ply cutter off-load table), guided by a laser pointing to the correct ply in reverse sequence of plies in that window, but with some gaps in the sequence. The gaps will be filled in at the next tray station, the final sorting station, which enables one operator to easily sort plies from trays that both offload operators have loaded onto trays. Therefore all plies in one kit are in correct reverse lay up sequence. Also, the plies will be verified at each station, thus tracking each ply from offload to lay up.

The individual kits can then be transported to either a freezer or directly to a lay up station. All plies from a given kit will arrive at the lay up station in reverse lay up sequence.

American GFM US120-CM10 with Pick and Distribute Demonstration Unit

NOTE: As indicated by the description of the two programs above, they require culture changes, as do many of the new programs and processes evolving , especially in Aerospace Composites. However these new processes and systems, will assure maximum production rates, with the numbers of typical errors either greatly reduced or eliminated, and will assure maximum material utilization, and provide consistently high production rates for each kit from one time to the next, and for one composites part manufactured by these processes, to the next part manufactured by these processes.

AGFM and GFM are suppliers to many major Aerospace Companies, plus other composites-related industries, and for several major Aircraft Composite Manufacturing Programs, supplying several types of machine tools/systems, including Ultrasonic Cutting Machines, Routing Machines, Combination Ultrasonic Cutting and Routing Machines,Flat Tape Laying Machines, Special Equipment/Systems and two of the Largest Automated, Integrated Composites Manufacturing Cells in the world.

Related Content

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More