CAMX 2019 exhibit preview: BTG Labs

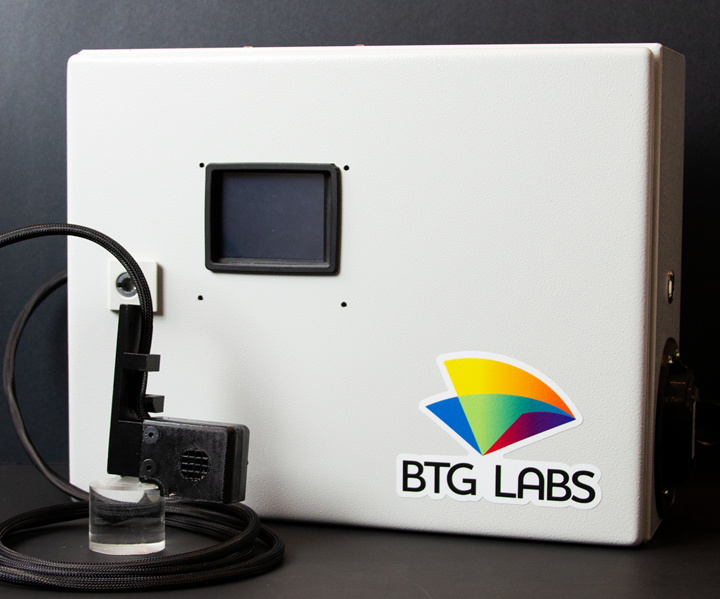

BTG Labs is featuring its recently launched Surface Analyst XA, an automated solution for evaluating material surfaces for bonding, coating, sealing, painting or printing.

Source | BTG Labs

BTG Labs (Cincinnati, Ohio, U.S.) is featuring its recently launched Surface Analyst XA, an automated solution for evaluating material surfaces for bonding, coating, sealing, painting or printing. The XA reportedly delivers real-time surface condition feedback to manufacturers, to ensure successful adhesion processes.

Also at CAMX, Dr. Giles Dillingham, CEO and chief scientist, will present a paper called “How Advanced Composite Materials Respond to Surface Treatment.”

The XA applies the technology from the company’s original handheld Surface Analyst to deposit a highly purified drop of water on a surface and then measure the contact angle. By automating this process, the XA increases the speed and efficiency by completing inspections on multiple surface points on a material surface at rates of up to 5,000 inspections per hour. As a result, the XA maps a surface across multiple points, ensuring consistency and uniformity of surface quality.

Source | BTG Labs

The XA measurement process is said to be non-destructive, using HPLC-grade water to prevent contamination of inspected material surfaces. Touchless measurement eliminates potential transfer of contamination from point to point, and the automation limits operator error and variation. Data capture and transfer to MES is automatic and completed via Archer software, providing statistical process control and long-term trend analysis.

The XA unit can be integrated into a production line using either a robot or linear actuator to move it from point to point, or it can be fixed in place on the line. Off-line cell inspections can also be conducted robotically or with a linear actuator. Self-implementing or full-line integration options are available.

The XA is customizable for various manufacturing processes and material shapes and sizes, accommodates TCP/IP/Serial integration, and outputs CSV files.

Related Content

-

Damage tolerance testing of sandwich composites: The sandwich CAI test

A new ASTM-standardized test method established in 2022 assesses the compression-loaded damage tolerance of sandwich composites.

-

HyImpulse, Adamant Composites linerless CFRP tank passes hydrostatic burst test

The liquid oxygen (LOX) tank, to be used in a HyImpulse smallsat launch vehicle, demonstrates the ability to withstand pressures well beyond the limits of its intended use.

-

Plant tour: Renegade Materials Corp., Miamisburg, Ohio, U.S.

Renegade Materials is known for high-performance prepregs for aerospace applications. Following its acquisition by Teijin in 2019, the company has expanded capacity and R&D efforts on a range of aerospace-targeted materials.

.jpg;width=70;height=70;mode=crop)