CAMX 2019 exhibit preview: Michelman

At CAMX 2019, Michelman is featuring its new line of Hydrosize carbon fiber sizing solutions.

Source | Michelman

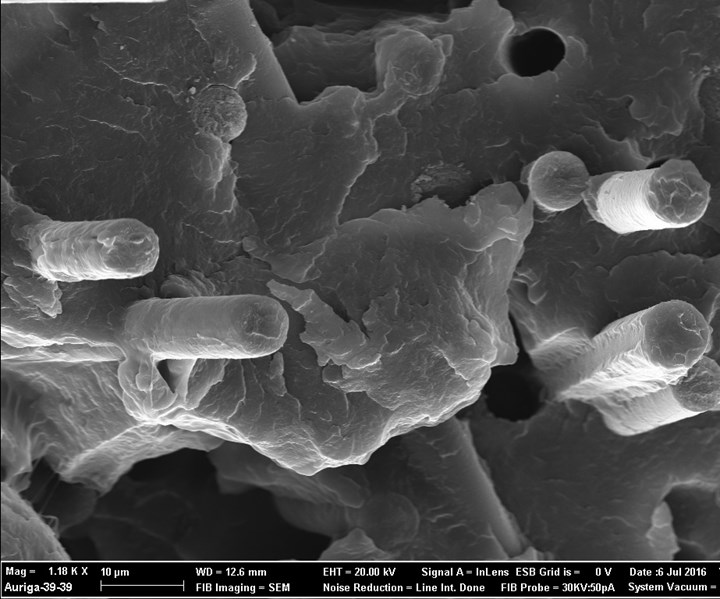

Michelman (Cincinnati, Ohio, U.S.), is featuring its new line of Hydrosize carbon fiber sizing solutions, designed to optimize interfacial adhesion between polymers and fibers. Four series of grades are available.

The Hydrosize Carbon 200 series is designed for polyamides including high-temperature applications, and is said to be APE, solvent, and VOC-free. This grade is intended for fiber-reinforced nylon composites requiring thermal stability, such as the manufacture of coolant pumps for the automotive industry. Other benefits of these small particle size dispersions are said to include ideal film-forming properties and high strand integrity.

The Hydrosize Carbon 300 series is formulated for polycarbonates (PC) and other PC blends such as PC-ABS. It is designed for high chemical resistance and interfacial adhesion to polymer systems. Applications include laptop cases or other electronic components.

The Hydrosize Carbon 400 series includes high-performance grades that reportedly can withstand the extreme processing temperatures that many high-temperature thermoplastics require. Appropriate materials include polyetheretherketone (PEEK), polyphenylene sulfide (PPS), polyetherimide (PEI) and others used to produce composite engine components. This series is designed for optimal thermal stability and mechanical properties, as well as low creep. It is suited for chopped carbon fiber applications.

The Hydrosize Carbon 700 series, currently under final stages of development, has been formulated to improve the performance of carbon fiber-reinforced vinyl ester composites, targeted specifically for sheet molding compound (SMC) applications. Its proprietary chemistry is said to increase adhesion between the carbon fiber and various vinyl ester compounds.

Also at CAMX 2019, Steve Bassetti, group marketing director, and Muhammad Iqbal, research chemist, both from Michelman’s Industrial Manufacturing Group, are presenting a technical paper titled “Effect of Sizing on the Interfacial and Mechanical Properties of Carbon Fiber (CF) Reinforced Polyamide (PA6,6) Composites.”

Related Content

-

Comprehensive service formulates standard, custom SMCs

CAMX 2024: As an SMC product manufacturer, Molding Products LLC provides SMC formulations and technical support for diverse markets, from R&D to post-production.

-

IDI Composites opens new global headquarters, manufacturing and technology center

The Noblesville, Indiana, facility includes SMC and BMC manufacturing, an R&D center and the company’s corporate headquarters.

-

Dieffenbacher acquires Schmidt & Heinzmann composites business

The acquisition, which includes all intangible assets of the business unit, will expand Dieffenbacher’s SMC delivery spectrum, enable potential for portfolio growth and synergies.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)