CAMX 2021 exhibit preview: CGTech

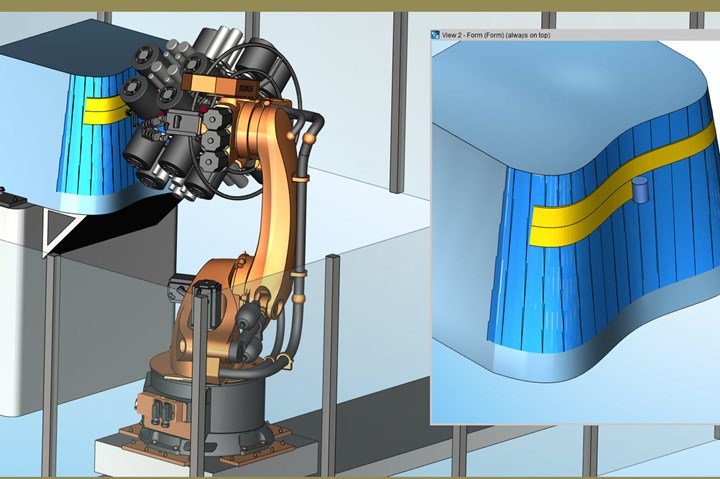

CGTech is to demonstrate VERICUT 9.2 simulation, composites and additive manufacturing capabilities.

Photo Credit: CGTech

CGTech (Irvine, Calif., U.S.) is demonstrating VERICUT 9.2 at CAMX 2021. VERICUT is the industry standard for simulating CNC machines to detect errors in traditional machining such as milling or turning, as well as additive manufacturing (AM) and composites.

The latest version of VERICUT is said to bring improvements to performance and collision detection, enhanced support for cutting tools and tool reporting, and more options for optimization in both Force and OptiPath. Users may optimize NC programs by setting target Chip Thickness along with any combination of machining limits in Force such as maximum cutting forces or spindle power and tool deflection.

VERICUT’s additive module simulates and verifies the capabilities of additive and hybrid CNC machines such as laser activity, power, material feed and gas flow. It also detect collisions between the machine and the part while identifying errors, voids and misplaced material. VERICUT allows users to arrange additive and machining operations in any order to check that all setups and holding fixtures work while verifying the finished part matches the design.

VERICUT Composite Simulation (VCS) is a simulated work environment for automated composites manufacturing. VCS simulates NC programs on a virtual machine including head changes, probing, knife-cutting and more. The simulated material can be inspected for stack thickness, ply offset, ply angle and other information to ensure that the program follows standards and requirements. VCS can automatically create a report showing simulation results and statistical information.

Additionally, CGTech’s Barry Kennemer is providing an on-demand presentation titled “Simulation Paves the Way for Productivity with Additive Manufacturing.” The presentation will cover the benefits of simulation software and AM such as:

- How simulation software helps designers create parts to suit their AM capabilities.

- Why simulating post-processed NC code on digital twin virtual machines is the best way to protect your investment into additive equipment.

- How simulation software can validate that planned operations and setups will work and those parts are producible.

- What a robust AM software can do beyond “building a part.”

Related Content

-

Active core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

-

Composite sidewall cover expands options for fire-safe rail components

R&D project by CG Rail explores use of carbon fiber-reinforced thermoplastics and recycled manufacturing scrap to meet fire safety, weight and volume targets.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.