CAMX 2022 exhibit preview: Innerspec Technologies

Taurus and Camus 3D ultrasonic inspection systems provide automated and semi-automated solutions for composite aerospace components.

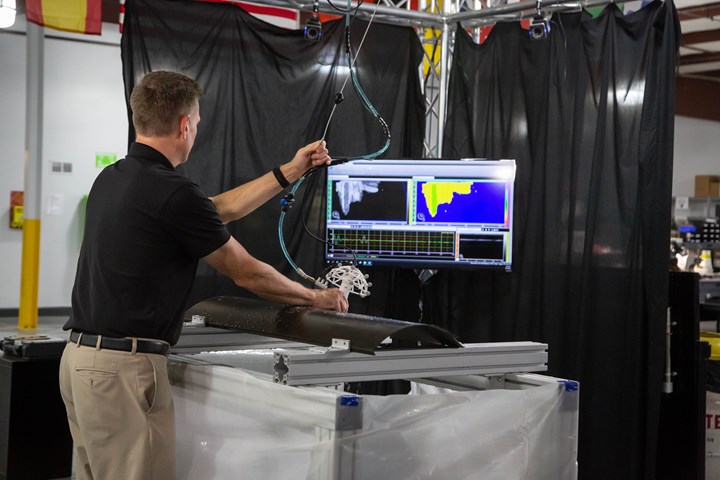

Taurus inspection system. Photo Credit: Innerspec Technologies

Innerspec Technologies’ (Forest, Va., U.S.) Taurus is an automated system for ultrasonic inspection of aerospace components using waterjet and air-coupled through-transmission (TTU) and/or pulse-echo (PE) techniques. The system includes one or two industrial robots mounted on linear tracks to provide maximum flexibility and performance for the inspection of very large and complex components. The robots can be fitted with standard and custom end effectors and yokes to adapt to complex geometries such as double curvatures, edges, cut-outs, radii, T or Ω stringers. Automatic tool changers permit adding other devices such as defect marking or laser scanning for teaching trajectories.

According to Innerspec Technolgoies, Taurus is a tested and proven solution that incorporates state-of-the-art hardware and software to provide unsurpassed levels of accuracy and productivity. It is said to be the most popular robotic inspection system in the market with more than 70 installations worldwide, and qualified by major aerospace manufacturers.

Feature include:

- Waterjet, local immersion, total immersion in external tank and air-coupled ultrasonic techniques

- Pulse/Echo (PE) and Thru-Transmission (TTU) with mono-element, dual frequency and phased array probes

- Multiple configuration options including a Taurus single robot; Taurus Twin two-robot configuration, which features twin robots with tracks facing each other; Taurus MRO, which features a single robot with a yoke for MRO inspections in a maintenance hangar

- Seven- to eight-axis robot mounted on a linear track permit inspections of very large components and complex geometries (double curvatures, edges, cut-outs, radii, T and Ω stringers)

- Real-time C-scans provide immediate feedback of coverage and quality of inspection

- Sonia instrumentation with InspectView software

Camus 3D composites inspection system. Photo Credit: Innerspec Technologies

Camus 3D is a semi-automated system for ultrasonic inspection of aerospace components, providing an alternative to multi-axis inspection robots and gantries. The system integrates an array of 3D cameras that track the position of the probe with a high-performance PAUT instruments to provide accurate, high-resolution C-scans of complex shaped parts. Camus 3D is said to be a flexible, accurate and affordable solution for inspection of composites and metallic components.

Features include:

- 3D cameras that eliminate encoders, wiring and electrical noise. These also permit semi-automated inspections (hand scanning, wireless encoding), and eliminate encoders on system retrofits.

- Phased array UT (32 to 128 channels) sensor with custom shoes to adapt to any geometry

- 3D cameras that track probe movement and provide encoding and full traceability of the inspection results

- Detection of defects as small as 1/8" diameter (3 mm) in laminated composites. Detects scattered porosity through back-wall attenuation, and provides a full thickness map of the part

- Inspection cell up to 1,000 ft2 (100 m2) of coverage, with larger cells available upon request

- Real-time C-scans provide immediate feedback of coverage and quality of inspection

- Upgradeable to fully-automated robotic inspection

- PAUT can be added to an existing line without the complex integration

- Qualified by major aerospace manufacturers

- Sonia instrumentation with InspectView software.

Both Taurus and Camus 3D systems are built by Innerspec in the U.S. with license from Tecnatom (San Sebastian de Los Reyes, Spain).

Related Content

-

Automated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Innovation in ultrasonic inspection and nondestructive testing

With increasingly complex structural components working their way into aerospace programs, the need for versatility in inspection and testing capabilities is growing.

.jpg;width=70;height=70;mode=crop)