Carbon Fiber Reinforced Nylon 12 for Injection Molding

CRP Technology’s new composite is 100% recycled from Windform XT 2.0 IMG industrial 3D printing material.

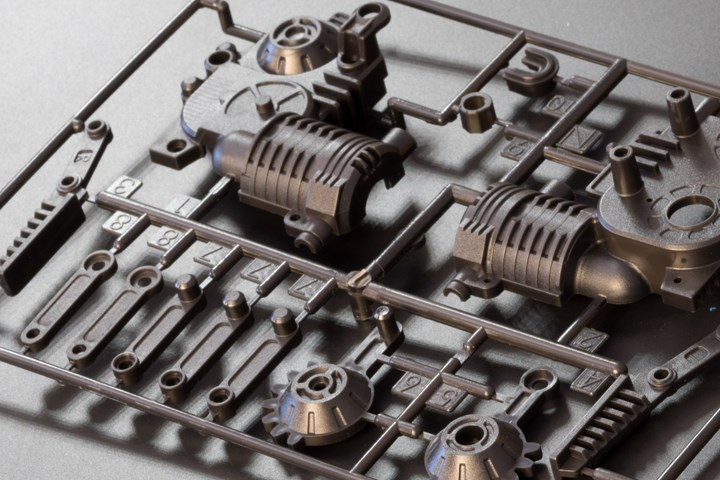

A new carbon fiber reinforced nylon 12 composite for injection molding is newly available from CRP Technology. Said to be the first of a family of sustainable materials for industrial production, Windform XT 2.0 IMG is 100% recycled from the company’s exhausted Windform XT2.0 industrial 3D printing material for laser sintering.

The Windform XT 2.0 IMG formulation boasts premium performance ranging from in high stiffness and resistance to shock to allowing for extreme detail accuracy even with thin thicknesses. Its excellent properties reportedly make it ideal for demanding applications in industries such as automotive, transport, e-mobility, agriculture, robotics and industrial design.

Said CRP Technology’s CEO and technical director Franco Cevolini, “For some time, we at CRP Technology have been studying an alternative and total use of those exhausted Windform powders for selective laser sintering, that fallen into disuse as they no longer meet our high quality standards…In this case, we regranulated the Windform XT 2.0 powder cake, and make it suitable for injection molding technology. The test phase ended with excellent results and now we are ready to sell it to those who manufacture on large volumes basis.”

Indeed, the high-quality injection molded parts made of Windform XT 2.0 IMG are said to exhibit the same performance of prototypes realized in additive manufacturing with Windform XT 2.0.

Related Content

-

CirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

-

Composites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.