Composites Evolution showcases high-performance prepregs, novel thermoplastic UD tapes

Composites Evolution highlights its Evopreg prepreg family, as well as PA6 tapes reinforced with UD carbon fiber for ATL, filament winding and compression molding.

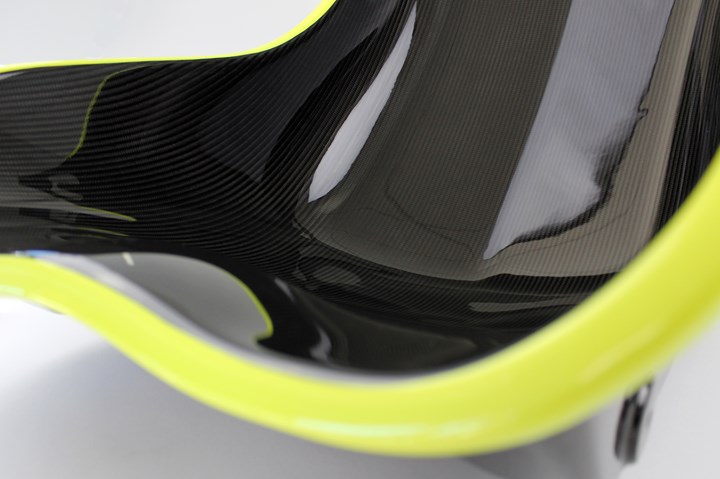

Photo Credit: Composites Evolution

Composites Evolution (Chesterfield, U.K.), a developer, manufacturer and supplier of prepregs for the production of lightweight structures, highlights its range of prepreg offerings and introduces a novel thermoplastic tape manufacturing capability.

Composites Evolution has a family of specialist prepregs for various applications, including Evopreg EPC epoxy component prepregs which are a range of pre-impregnated fabrics suitable for molding into high-performance, lightweight, structural components; Evopreg EPT epoxy tooling prepregs which have been designed to help composite tooling manufacturers improve the flexibility and efficiency of their tooling manufacturing processes; and Evopreg PFC fire-retardant prepregs a 100% bio-derived alternative to phenolics for applications where fire performance is a critical requirement, such as battery boxes.

The company also highlights its Evopreg ampliTex, which combines high-performance Evopreg epoxy resin systems with Bcomp’s (Fribourg, Switzerland) ampliTex flax reinforcements for outstanding performance. Composites Evolution has developed a rear wing from a Ginetta G56 GTA GT4 racecar with this material.

Further, the company’s range Evopreg PA thermoplastic tapes range, initially launched at Advanced Engineering, are manufactured from polyamide 6 (PA6) polymer with unidirectional (UD) carbon fiber. They are suitable for automated tape laying (ATL), filament winding and compression molding processes.

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.