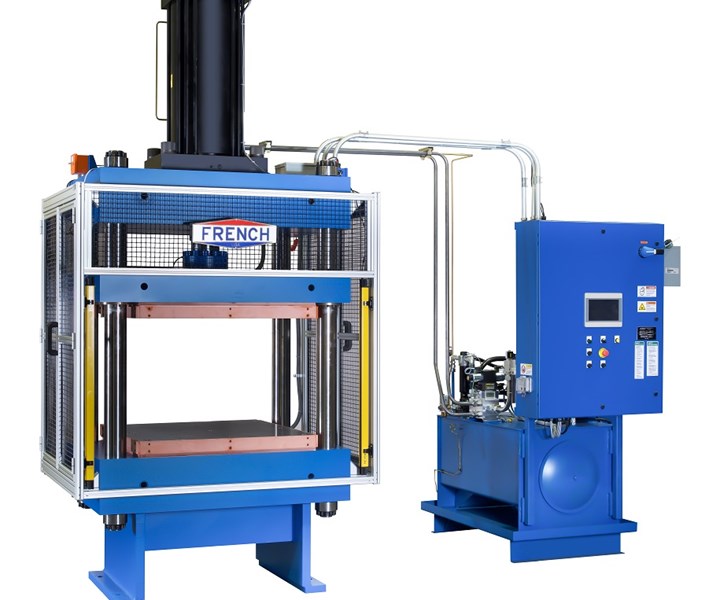

Down-acting hydraulic compression press designed for composite molding

French Oil & Mill Machinery’s 200-ton hydraulic press reduces installation costs and provides a low work height.

Share

Source | French Oil & Mill Machinery Co.

French Oil Mill Machinery Co. (Piqua, Ohio, U.S.) has designed a 200-ton, four-post hydraulic compression press designed for composite molding. The press is fitted with 40" square heated platens machined from solid steel plate then fitted with shaded watt density cartridge heating elements. The heating is divided into two control zones to provide a steady state operating temperature up to 500°F.

The down-acting press design reduces installation costs and provides a low work height. A heavy duty double acting 30" stroke JIC cylinder applies up to 200 tons of force. The cylinder is coupling connected to the press moving bolster to aid in any misalignment and to extend the life of the cylinder seals and bolster bushings. Strain rods were machined from solid steel 1045 as a matched set to ensure correct proportional loading and exact parallelism of matching components.

The hydraulic system consists of a self-contained oil hydraulic unit with a steel constructed reservoir with hydraulic pump combination driven by an energy efficient motor (TEFC). This pump-motor combination is said to enable fast closing, opening and adjustable tonnage of the press. The hydraulic unit is floor-level mounted next to the press.

The compression press control system is a microprocessor-based system, designed to improve quality through better processing accuracy, repeatability, versatile process-control programming and monitoring of data for analysis. The system is said to be operator-friendly and easily used to control most molding applications.

Components of the system include an Allen Bradley PLC, a color touchscreen operator interface, press pushbuttons for operation and a NEMA-type enclosure mounted to the hydraulic system next to the press. The interface screen provides for display and programming of the machine recipe and includes temperature set-point, pressure set-points and time. The screen displays:

- real-time data of all press data points,

- actual vs. setpoint for time, platen temperature and pressure values throughout the cycle,

- recipe configuration for pressure and temperature parameters for automatic cycle,

- manual mode set-point control,

- visual alarms for temperature and pressure faults, and

- display and programming of temperature loop P.I.D. parameters.

In accordance with safety regulations and best practices, the press sides and rear have an extruded aluminum frame with expanded metal inter guards. Light curtains restrict unsafe access to the press front.

As with all French and TMP presses, the press system is reported to be tested and passed customer inspection prior to shipment. All parts and labor are guaranteed by the company against defects and workmanship and French says its in-house service technicians and engineers are available for start-up assistance, service and any necessary trouble-shooting.

Related Content

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

.jpg;width=70;height=70;mode=crop)