Electroimpact launches plug-and-play AFP system

Automation and automated fiber and tape placement specialist Electroimpact has introduced Scorpion, a new modular plug-and-play automated fiber placement (AFP) system designed for research and laboratory applications.

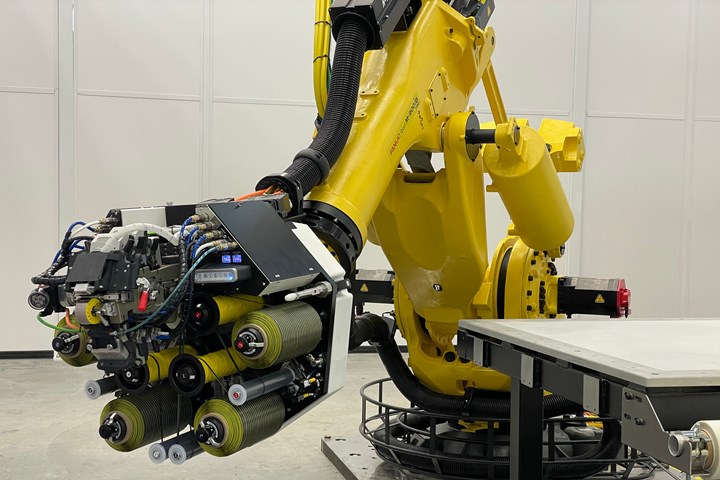

Electroimpact Scorpion automated fiber placement system. Photo Credit: Electroimpact

Automation and automated fiber and tape placement specialist Electroimpact (Mukilteo, Wash., U.S.) has introduced Scorpion, a new modular plug-and-play automated fiber placement (AFP) system designed for research and laboratory applications. Electroimpact calls Scorpion an AFP4.0 system that includes a Fanuc M-900iB/700 robot, a four-lane 0.25-inch AFP head, a 3 x 1.5-meter flat vacuum charge table, a laser safety enclosure and operator interface.

Electroimpact Scorpion automated fiber placement system inside enclosure with vacuum table.

Photo Credit: Electroimpact

The AFP head , which can lay down thermoset or thermoplastic prepreg fiber or dry fiber, features servo-powered creels and offers a two-segment eye-safe laser or a four-segment high-output laser. Speed capabilities include 100 m/min initial feed, 75 m/min refeed and 75 m/min cut. Standard in-process inspection covers tow ends and process errors; optional inspection technologies cover laps/gaps, foreign object debris (FOD) and backer detection. System expansion options include a part rotator, eight- or 16-lane head and 0.125- or 0.5-inch tows.

Related Content

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.