Graphene nanotube-enhanced gelcoats enable powder coating

Gelcoat modified by use of graphene nanotubes imparts conductivity to the surface of composite parts and enables powder coating instead of liquid painting.

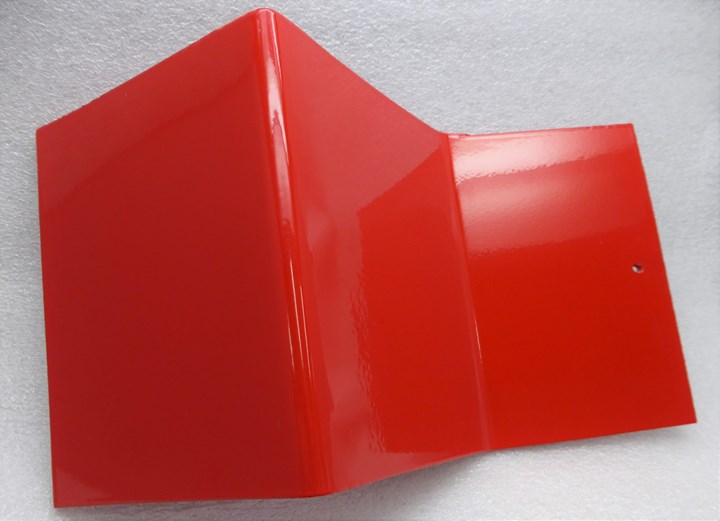

Powder coating on a composite part with graphene nanotube-enhanced gelcoat. Photo Credit: TIGER Coatings GmbH & Co. KG

A collaboration between OCSiAl (Columbus, Ohio, U.S.), BÜFA Composite Systems (Oldenburg, Germany) and TIGER Coatings (Wels, Austria) recently developed gelcoats enhanced with graphene nanotubes that impart conductivity to the gelcoat and make it receptive to powder coating. Use of powder coating instead of liquid painting, says TIGER Coatings, offers processing ease, color flexibility, chemical resistance, and zero emissions for automotive, marine, aerospace and sanitary applications. The novel conductive gelcoat, which offers permanent and stable resistivity of 106 Ω/sq, is a byproduct of BÜFA’s Conductive-Tooling gelcoat series. It has been modified for powder coating compatibility. OCSiAl is supplying the graphene nanotubes and BÜFA is manufacturing the gelcoat.