Heating platens deliver precise, uniform compression molding temperature control

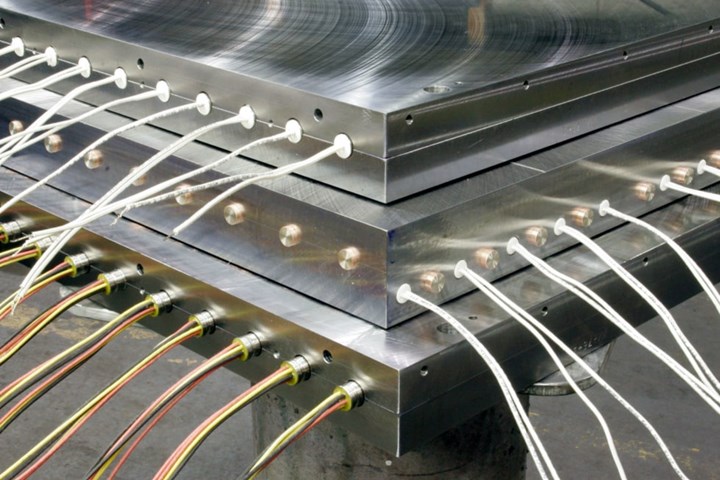

CAMX 2023: Venango Machine features MultiZone heating platens with a control system included, capable of reducing mold surface temperature variation by almost 400% during the compression molding process.

Venango Machine Co. Inc.’s (Erie, Penn., U.S.) MultiZone heating platens with an included control system are said to reduce mold surface temperature variation by almost 400%. This delivers the precise and uniform control necessary when compression molding for a good product and faster recoveries.

In compression molding, as the value of the material and part rises so does the importance of controlling the uniformity of heat transfer to the mold cavity. Single-zone heating platens can not correct temperature variation across the mold face which negatively impacts manufacturing, part quality and increases scrap rates. The company’s MultiZone heating platens are designed to offer an alternative solution, giving molders six sigma capabilities

In a comparison of single-zone versus MultiZone heating platens, temperature uniformity improved from 25° off target to only 0.4°. Further, the process capability index (CPK) increased from -1.47 to 2.94 while lowering the standard deviation from 3.2 to 1.08. During molding, the process window reportedly dropped from ±9.6 to ±3.2, ultimately leading to shorter cure times and lower scrap rates.

The company’s Single-Zone and MultiZone platen control panels include:

- Initial control panel engineering design and specifications

- Standalone control panel options

- Single-zone control panel options with complete operator interface HMI system

- MultiZone control panel options with complete operator interface HMI system

- Control panel schematics

- On-site setup and training for electric platen control panels

- On-site troubleshooting for electric platens and control panels

Venango Machine manufactures steam, hot oil, electrically heated (cartridge and strip), high-temperature and heating/cooling platens for hydraulic press and compression molding applications. Platens accommodate round, square or rectangular designs for any application. Regardless of press size or type, Venango designs new platens or simply manufacture platens to OEM specifications.

Related Content

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.