High-definition part surface quality on injection molded parts

RocTool (Le Bourget du Lac, France; Charlotte, NC, US) has introduced a new technology, called HD Plastics, that applies the company's fast, high heating and fast cooling to the improvement and optimization of thermoplastic resin systems in injection molding applications.

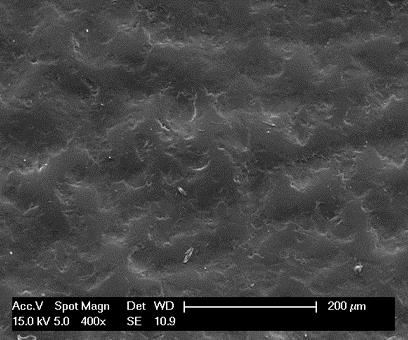

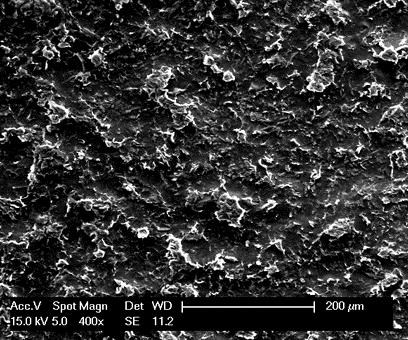

RocTool (Le Bourget du Lac, France; Charlotte, NC, US) has introduced a new technology, called HD Plastics, that applies the company's fast, high heating and fast cooling to the improvement and optimization of thermoplastic resin systems in injection molding applications. With the technology, RocTool says the level of the tool surface replication goes up to 97.2%, providing product designers premium looks, high-gloss possibilities and excellent texture matching. RocTool says the improved material flow made possible by the company's high-heat molding technology unlocks design rules and maximizes the potential for molders to create thin-wall applications. RocTool has begun building a materials database that will be used to gauge overall surface quality for a variety of resins molded using the HD Plastics technology. The database will record level of replication of the tool surface, weld line strength and flow length. Resins targeted include commodity, engineering and high-performance polymers, including PEEK, PEI and those with high filler content. The technology is also applicable to fiber-rreinforced materials.

Related Content

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

-

BlueHalo launches next generation of Intense Eye UAS

Unmanned aerial system (UAS) from BlueHalo featuring an HX5 injection-molded chassis from Alpine Advanced Materials is said to be lighter, stronger and more efficient than aerospace-grade aluminum.

-

Seat frame demonstrates next-generation autocomposites design

Light weight, simplified/cost-effective manufacturing, passenger comfort and safety informed materials and process innovations and won awards for the 2022 Toyota Tundra‘s second-row seat frame.