Industrial CNC combats composite machining challenges

CAMX 2023: C.R. Onsrud invites attendees to learn more about its five-axis Q-Series and other composite CNC machinery options that offer fast, accurate material processing.

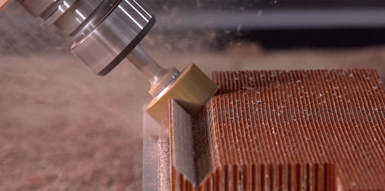

C.R. Onsrud (Troutman, N.C., U.S.) highlights the Q-Series five-axis industrial CNC machine and other CNC options for fast, accurate processing of composites.

The North Carolina-made five-axis Q-Series was designed, engineered and manufactured to combat composites’ ability to turn material to scrap, quickly wear out tools and create a lot of debris. According to the company, this CNC machine can produce sharp angles for quick, clean cuts of the complex composite, thermoformed plastic, foam board, wood, aluminum, carbon fiber, fiberglass and other advanced materials, additives and binding agents.

To accurately machine composites, Onsrud advises manufactures to look for:

(1) An abrasion-resistant machine build that uses high-quality, industrial-grade components that can withstand abrasive environments. The machine needs to properly seal and cover the mechanical and electronic components. Since some composite dusts are electrically conductive, they can short out machine circuits. With protected motion-controlled components and drives, users can maintain precise, linear motion and extend the life of the machine. Plus, there are additional options engineered for manufacturers working with composites (e.g., air knives clear harmful debris away from the cutting area).

(2) A fully enclosed machine with sufficient dust collection to keep operators safe from potentially hazardous composite dusts.

(3) High (18,000-24,000) rpm, low torque spindles which are more efficient, reduce cycle time, lengthen tool life and improve overall spindle reliability. Although, if machining metal, Onsrud says to consider a higher rpm range.

(4) Fixturing options (e.g., vacuum hold-down and pneumatic fixtures) that offer efficient material holding for the workpiece being cut and a fast way to change out parts without worrying about machining through a clamp or a fixture.

(5) Right-sized work envelope. Composites and molds can vary dramatically in size. The Q-Series has a work envelope of 60′ (L) × 12′ (W) × 40″ (H) and Onsrud builds machines that are larger.

“We’ve seen firsthand the game-changing impact a CNC machine can have in manufacturing composites, from increasing a shop’s capacity to improving margins while giving businesses control over the design, manufacturing and quality of their end product,” Ken Stissel, national sales manager, C.R. Onsrud, concludes.

Related Content

-

Highly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

-

Graphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

-

Concentrated smooth dispersion simplifies electrical conductivity applications

CAMX 2024: Total Resin presents Total Nanotüp, a concentrated dispersion of carbon nanotubes in a bifunctional reactive monomer for polyester, vinyl ester, melamine and acrylic resins.