Infusion processing flow mesh range, technical composites expertise

JEC World 2024: Expo-Net promotes 100% recyclable extruded thermoplastic resin flow mesh products, an updated technical processing guide and highlights its successful work with industry partners.

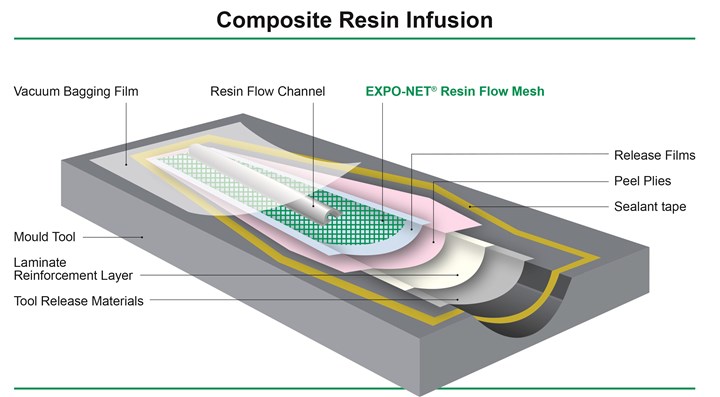

Expo-Net Danmark A/S (Hjørring, Denmark) is promoting its extensive range of 100% recyclable extruded thermoplastic resin flow meshes. The flow mesh products developed and produced by the company are extensively used in composites manufacturing as essential vacuum infusion processing aids; during the new product development stage for large parts, such as for a wind generator blade or a yacht deck, up to four different custom-made resin flow mesh grades can be used in specific areas of an infused part to increase productivity and to avoid premature resin hardening and air voids. Expo-Net has been supplying wind blade producers for more than 25 years, and cites itself as a highly innovative, technically advanced, problem-solving partner.

During 2023, Expo-Net continued to develop its technical knowledge, working closely with TechCollege (Aalborg, Denmark). A vocational education and training (VET) institute with more than 3,000 full-time students, one of TechCollege’s specialist offerings is a range of training courses on composite materials and processing. Testing of the 13 different resin flow mesh product grades supplied by Expo-Net was completed last year using the college’s facilities and support. The test program, instigated by Expo-Net to help customers better understand the rheological impact of different flow mesh grades and types, was developed and conducted by Mark Holmgaard Christensen, Expo-Net’s plant manager. Christensen is also a composite specialist development engineer and one of the examiners for the TechCollege composite training course.

Expo-Net has published the latest “Vacuum Infusion Resin Flow Mesh Technical Processing Guide 2024,” which provides comparative data on all Expo-Net flow mesh grades currently available. The guide enables an OEM or Tier 1 composite part producer to select the best flow mesh grades to use in different areas of a mold to consistently obtain the desired resin infusion speed and final part quality. Visitors to the Expo-Net booth stand will be able to hear about future developments, learn how Expo-Net can assist customers in more detail and obtain a copy of the updated technical processing guide.

Expo-Net is a key supplier to a wide variety of customers and markets worldwide, supplying both directly and via approved supply chain distributors and kitting partners. The Expo-Net team provides a flexible, responsive customer service, customized products, technical support and a reliable supply chain delivery service. Expo-Net is also committed to its ongoing program focused on sustainability and net zero.

Visit Expo-Net at Booth P78 in Hall 5A.

Related Content

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.