JEC World 2018 preview: Krempel

Progress for 3D components – new prepreg system from KREMPEL

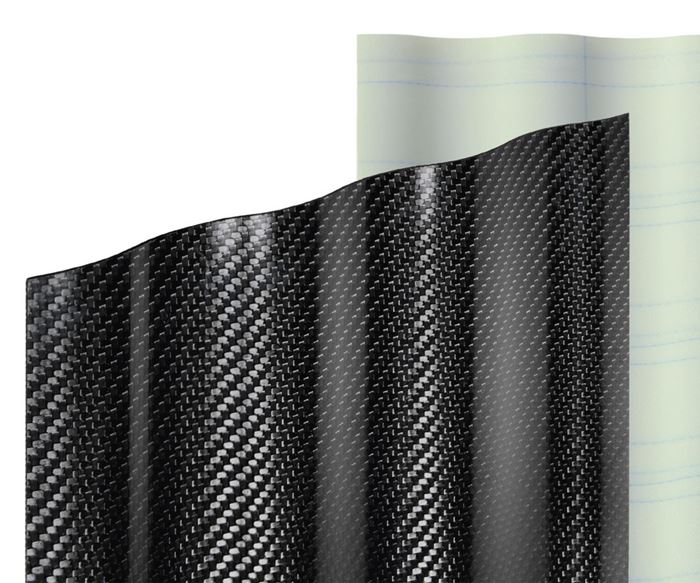

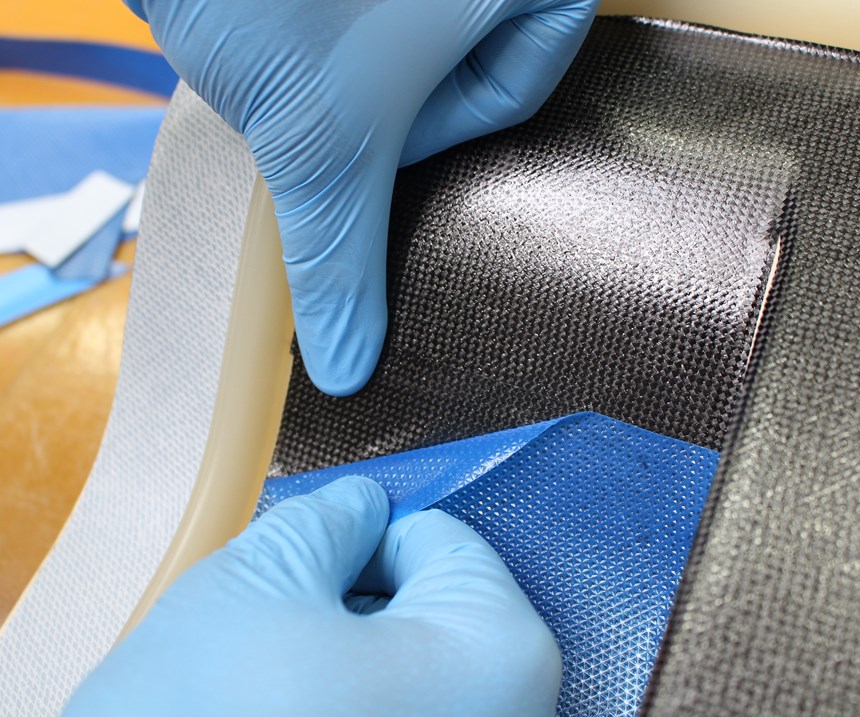

With the new Prepreg system BD for 3D components, KREMPEL has achieved an outstanding combination of the material characteristics which are essential for success: the new formulation BD U286 has been developed with particular attention to the areas of drapability, tack and the elimination of white spots. The system boasts very good heat resistance at a high glass transition temperature and crystal-clear shiny surfaces. In addition to its use in motorsport, aviation, engineering, and medical technology, the matrix employed is suitable for a multitude of other applications up to 140 oC.

Thomas Mozer, applications technology manager in composites at KREMPEL gives his insights into the development criteria which are important in this respect:

“Dimensional stability during heat exposure requires particular attention. The characteristic value measured for this material quality is the glass transition temperature Tg. This can vary considerably, depending on the measurement method and its implementation. This metrological difference can lead to serious differences in performance, for instance whether components which are heated by the sun to 80 oC and beyond remain structurally stable or soften again. A crucial element in our development work was therefore to validly achieve a Tg value of at least 120 oC by means of dynamic-mechanical thermo-analysis (DMTA) to aviation standards. The result is that our Prepreg system BD is absolutely reliable in use at temperatures up to and including 140 oC.”

KREMPEL’s answer to the growing diversity of worldwide applications and manufacturer-specific requirements is tailor-made prepreg variations. “To achieve the desired values of pressure resistance, tensile strength, modulus of elasticity and other material characteristics, we manufacture the prepreg system BD with the fibres or textiles best suited to the task, whether made from carbon, glass, aramid or other materials. As an independent manufacturer we are not tied to particular raw materials, our only obligation is to optimum workmanship,” says Marcus Münch, area sales manager for composites at KREMPEL. “In the same spirit, as development partners in test series we also use special backing materials and help to implement these in production. We gain additional scope for development by modifying the resin recipe to obtain special characteristics, such as UV resistance.” KREMPEL guarantees consistently high product quality for all prepreg variations, and manufactures to DIN EN 9100 standards.

Related Content

-

McLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.