L&L Products introduces FST-compliant interior edge and core filler compound

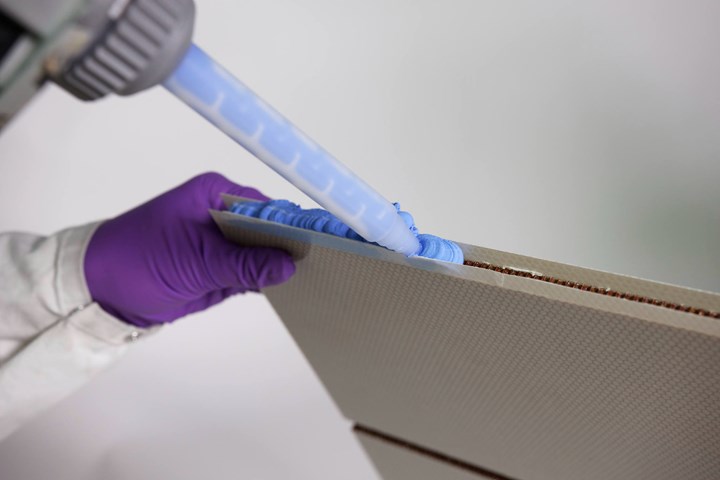

L&L Reinforce L-9060 improves the traditionally manual process of other two-component honeycomb panel reinforcements, optimizing process, quality and waste.

Photo Credit: L&L Products.

L&L Products (Strasbourg, France and Romeo, Mich., U.S.) has launched a new FST aircraft interior edge and core filler compound. L&L Reinforce L-9060 is reported to bring a new approach to fill and reinforce aerospace interior sandwich panels by providing a solution to improve the traditionally manual process of other two-component honeycomb panel reinforcements. L&L says the compound addresses process, quality and waste issues for aerospace customers while meeting all industry regulatory requirements.

L&L Reinforce L-9060 is an accurate mixing of two components. Because it requires no hand mixing, it is clean, easy to use and results in no waste. The compound is suitable for automatic metering pumps; equipment to process the cartridge is a standard 400 ml manual or pneumatic gun.

Further, the product has an ultra-lightweight density (0.55 kg) to help reduce the overall weight of aircrafts, for additional CO2 emissions and fuel consumption reduction. L&L Reinforce L-9060 is compliant with FAR/JAR 25.853, which reinforces safety on board and reduces certification cost and it does not contain carcinogenic, mutagenic or reprotoxic (CMR) substances, is REACH compliant and contains no odor.

According to L&L, extrusion of L-9060 is easy, and results in simple application to the honeycomb cells. The material can be spread along edges and easily smoothed with a spatula. L-9060 cures at room temperature and can be milled or sanded 2.5 hours after application. Panels are then reinforced and protected by L-9060, which creates a rigid and impact-resistant reinforcement. L-9060 is also said to create faster curing and more efficient processing methods than the traditional method at a lower cost. In addition, the unfinished two-component cartridge can be closed and kept at room temperature for future use, avoiding unnecessary waste.

Technical information could be discussed with L&L’s team and distributors or found directly on the company’s website. Samples are available on request.

Related Content

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.