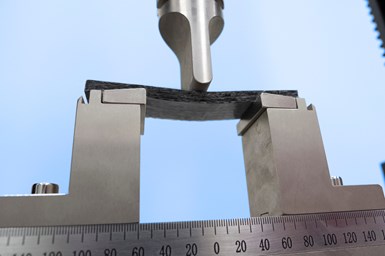

Manna Laminates organosheet laminate aims for automotive crash applications

Formtex organosheets are ideal for the manufacturing of structural and semi-structural automotive parts with high energy absorption, high impact resistance and additional multi-axial reinforcement.

Share

Photo Credit: Manna Laminates

Manna Laminates (Misgav, Israel) reports that, after four years of development, it is introducing its Formtex family of semi-raw, thick organosheet laminate materials, which are said to meet the most stringent specifications for automotive crash applications.

Formtex is made using advanced woven fabric or layered UD tape, reinforced with continuous fiber thermoplastics (CFT). According to the company, the laminates can be customized per part or industry requirement, making it ideal for quasi-isotropic-loaded hybrid parts. The result is said to be an innovative, affordable material that boasts outstanding quality and performance capabilities.

Moreover, says Manna Laminates, Formtex provides a significant advantage for automotive crash-testing applications and even electric vehicles (EV) battery casings because of its high energy absorption, high impact resistance and the thickness of the laminate itself, which further provides multi-axial reinforcement. It can also accommodate the need for location-specific strength, flame retardancy and electrical and thermal conductivity.

Photo Credit: Manna Laminates

Kobi Goldenberg, managing director of Manna notes that, while Formtex is mostly used for parts with large surface areas, it can also be used as an insert for local reinforcement in overmolding processes. One application example for this application is the company’s newly awarded Front End Module (FEM) carrier project for a European car platform. The three preheated strips of organosheet were placed on the cavity side of the injection mold and backfilled with 30% LFT-PP, eliminating the need for several heavy stamped steel brackets on the sides of the front-end module carrier, while still meeting front crash requirements and engine hood-latch load constraints.

Using its innovative impregnation and consolidation process, Manna adds that it can manufacture thick laminates up to 10 mm in a single step with shorter thermal history and superior mechanical and delamination resistance properties.

Formtex is available in a wide range of fiber/resin combinations and product formats. Fiber materials include E-glass and carbon fiber, and resin materials include PP, PA6, HDPE, LDPE, PC and more. It can be supplied as a rectangular-cut laminate or cut to shape.

Related Content

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Composites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.