Nanocomposite studies show potential for enhancing resin properties

CAMX 2024: Nanopoxy and Nione are presenting a session describing tests and results of incorporating niobium nanoparticles into epoxy resins.

Nanopoxy (Santa Catarina, Brazil), in partnership with Nione LTDA (Içara, Brazil) is presenting the talk, “The Future of Smart Composites: Performance-Enhanced Materials Enabled by Nanoniobium,” on Wednesday, Sept. 11 from 11:00 – 11:25 a.m. in the CAMX Theater. Nanopoxy invites all interested parties to attend.

Epoxy resins are widely recognized for their optimal properties, but they face challenges such as environmental stress cracking (ESC) and low thermal conductivity. This session will explore the incorporation of niobium nanoparticles (NbNPs) into an epoxy resin matrix to overcome these limitations.

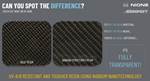

A manual lamination epoxy system with the inclusion of NbNPs has been tested, and findings will be presented. Nanopoxy says that the results show promise. Dynamic mechanical analysis (DMA) revealed significant improvements in the material’s toughness, with an increase from ~250 MPa before exposure in a weathering chamber to ~400 MPa after exposure. Furthermore, the nanocomposite has demonstrated improved vibration damping compared to pure epoxy resin while maintaining original glass transition temperature (Tg) and transparency.

Other benefits include approximately 30% improved chemical resistance, uniform surface roughness after polishing and approximately 50% increased UV resistance. Tests were performed before and after 200 hours of exposure in a weathering chamber, confirming the durability and effectiveness of the nanocomposite.

These advances suggest that incorporating NbNPs into epoxy resins could significantly improve several properties of the material, making it a promising candidate for a variety of high-performance composite applications. Potential application areas include the aerospace, automotive, and construction industries, where durability and strength are crucial.

The topic was initially presented at JEC World 2024 where it received great attention from the scientific and industrial community.

Related Content

-

From the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Bio-based epoxy, recycled materials increase sustainability of all-terrain snowboards

Aiming for a smaller environmental footprint while maintaining high performance, Salomon’s Highpath snowboard line incorporates bio-based epoxy, glass and basalt fiber stringers and recycled materials.