Oxford Advanced Surfaces water-based surface treatment reduces surface preparation time by 90%

Kotefast improves efficiency and productivity in the preparation of complex plastic and composite parts.

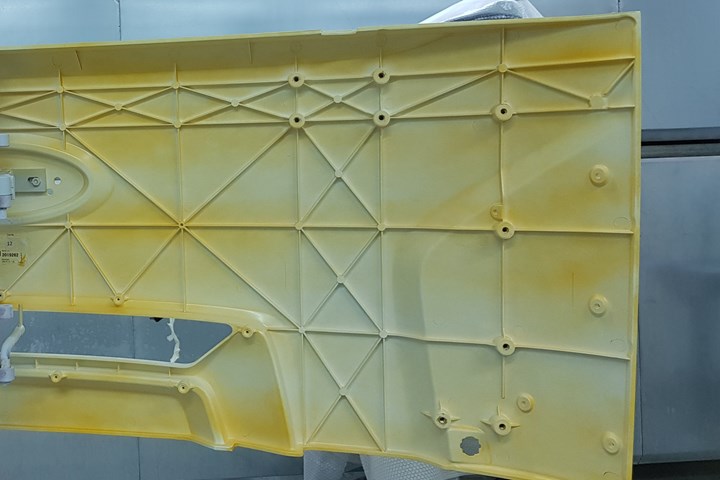

Photo Credit: Oxford Advanced Surfaces

Oxford Advanced Surfaces (OAS, Begbroke, U.K.) has developed a new water-based surface preparation treatment, Kotefast, that reportedly reduces surface preparation time by more than 90% compared to the conventional sanding approach. Kotefast can be used for the painting or lacquering of a wide range of composite and plastic surfaces.

Kotefast is available in spray formulations to reach difficult areas such as internal corners, difficult angles and blind voids, and as a result, delivers significant improvement in quality and consistency. Kotefast is suitable for use in both manual and automated processes, and has improved adhesion to the surface substrate via chemical bonding. Further, as a water-based formulation, the treatment is said to avoid environmental challenges which arise with sanding.

Kotefast has also been rigorously tested, OAS says, such as the truck panel (shown above). Treatment was time recorded at less than 15 minutes. An identical panel took three hours to prepare using the usual method of manual sanding, indicating a time saving of more than 90%. The treatment product is currently being used by two OEMs with the goal for full integration.

.jpg;maxWidth=300;quality=90)