Perforation technologies available for composite materials

CAMX 2023: Stewarts of America offers precision tooling, machinery, equipment and contract converting services to perforate prepreg films, composite panels, laminates and more.

Share

Read Next

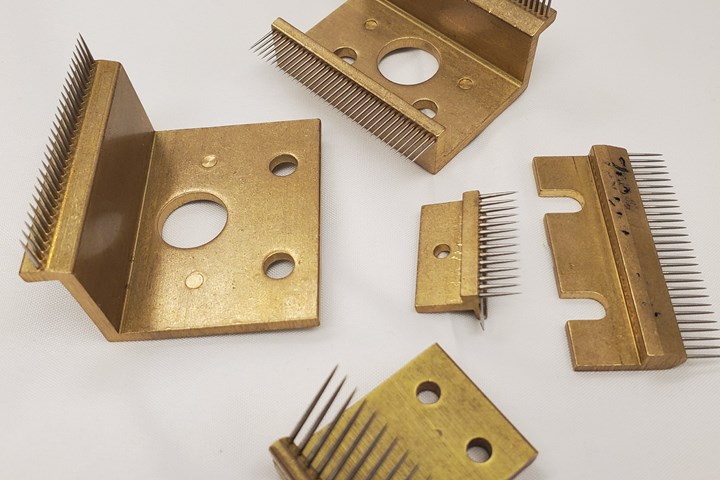

Stewarts of America (Greenville, S.C., U.S.) specialize in the the manufacture of pins, pinned products and perforating technologies for the composites industry. The company manufactures pinned weft plates for all makes and models of multiaxial machinery — including Karl Mayer, Liba and Malimo, Copmax, Maxtronic, etc. — and offers precision tooling, machinery, equipment and contract converting services for nano, micro and macro perforating of prepreg films, composite panels, laminates and more.

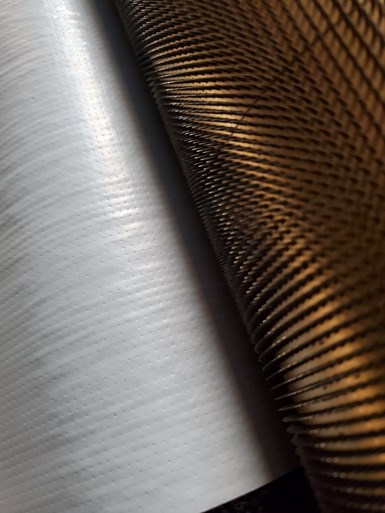

The standard rotary method of perforating typically involves a pinned/needle roller or other tool that pushes against an anvil roll. The roller may be heated or run at room temperature. The web is sandwiched between these rollers, and the pins are forced though the substrate, creating the perforations.

A wide variety of pin sizes and pin patterns are available to create a broad array of hole sizes and pattern specifications based on customer or product requirements. The perforation size and pattern affect the transfer of air, water vapor or liquid through the material. These perforations can be accurately controlled to create a value-add to the in-process or finished material, according to the company. Perforations can also be designed to have multiple benefits such as an easy-tear line that doubles as steam ventilation applications, or an air-escape hole with perforations laid out in the pattern of a product logo, removing the requirement and cost of printing the logo. The holes created can be nano, micro or macro perforations and can be round apertures, slits or impressions.

There are basic (manual), intermediate (semi-automatic) and advanced automated (fully automatic) options available. These quick-change technologies may also be combined with other automation methods to make the process truly hands-free for machine operators.

Nano, micro and macro perforating often requires different anvil rollers to be used with the perforating tooling. These can consist of brush rollers, felt-covered rollers, rubber rollers, silicone-covered rollers or grooved rollers. These, too, can be placed on a quick-change system for fast changeouts. Often, because anvil rollers will wear in spots, the quick-change option is said to enable the unit’s components to be rotated out on a timed basis so that a fresh area of a roller can be used against the tooling, ensuring optimum and repetitively accurate hole sizes.

Related Content

-

Unsaturated polyester resin exhibits flame-retardant properties

CAMX 2024: Polynt is demonstrating its halogen-free A 6104 A resin at the Composites One Demo Booth in the making of a battery tray using a silicone bag closed mold process.

-

Graphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

-

Getting ready for CAMX 2024

The Composites and Advanced Materials Expo’s 10th anniversary trade show and conference will be held in San Diego from Sept. 9-12, 2024.