Plyable secures $3.2 million investment to advance custom composite marketplace solution

Funding from Maven Capital Partners, Solvay Ventures and VC Forward Partners backs growth of time- and cost-saving digital composite tooling product.

Composite mold producer and AI-driven startup Plyable Ltd. (Oxford, U.K.) has received a total of $4.25 million to fund the growth of its time- and cost-saving digital composite tooling software, while expanding Plyable’s business footprint in Europe and North America. The latest $3.2 million investment was led by Maven Capital Partners, with support from Solvay Ventures, the venture capital fund of Solvay (Alpharetta, Ga., U.S.) and VC Forward Partners.

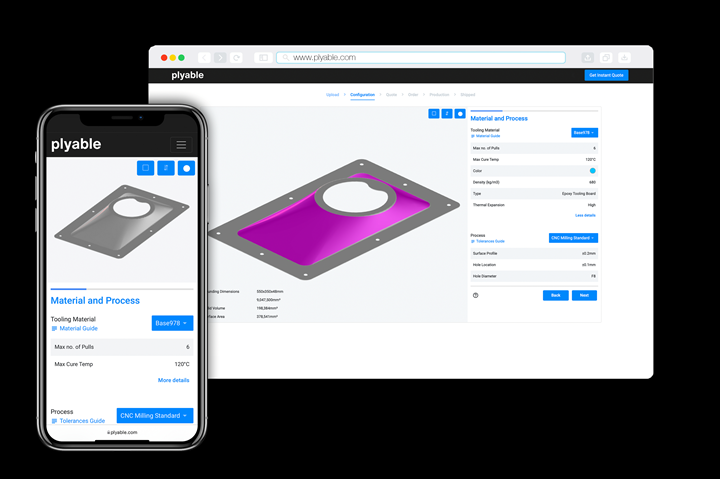

Plyable’s “one-stop shop” technology model enables engineers to drop a CAD file for entire assemblies — part, mold, jigs and off-the-shelf items — into the company’s web app to receive instant, AI-generated recommendations for optimum mold design, including suggestions and digital simulations, before arranging production, inspection and delivery. According to the company, the solution will instantly validate design decisions, simultaneously cost and specify the project production time, and take care of the end-to-end procurement process for composites engineers.

“The world of composites today is a vast green field and a highly fragmented $100 billion artisan market — one that’s been overlooked, until now,” Martin Oughton, Plyable founder, says. “We’re delighted that Maven, Solvay and Forward Partners share our vision and are supporting Plyable to continue to innovate and modernize the composites industry.”

Plyable customer GKN Aerospace (Redditch, U.K.) currently receives its molds 44% faster than the traditional supply chain, and at a 20% cheaper cost than traditional supplier offers, thanks to the digital solution (see another similar example, “Vertical Aerospace used Plyable to go from CAD to first flight in less than 90 days”).

“Plyable’s unique digital solution allows customers of all sizes to accelerate the pace of developing composite parts while also lowering the overall cost,” Coppelia Marincovic, partner at Solvay Ventures, notes. “Applying digital solutions, Plyable is helping to increase the efficiency of the supply chain and supporting overall growth in the composites industry.”

Plyable was also selected to be part of Boeing’s (Chicago, Ill., U.S.) Accelerator Programme in 2020. Nichola Bates, head of Global Accelerators and Innovation Programs at Boeing states that the company is looking forward to seeing how this newest investment will drive the next phase of Plyable’s journey, noting that Boeing “will continue to support them.”

Related Content

-

Jamco America partners with Airtech for 3DP tool recycling

Aerospace manufacturer joins forces with composite materials company to achieve sustainable manufacturing practices that overcome traditional composite layup tooling.

-

Corebon induction heating

This sidebar to CW’s August 2024 feature article reviews this technology for more efficient composites manufacturing and why it aligns with Koridion active core molding.

-

Metal AM advances in composite tooling, Part 2

Toolmakers and molders continue to realize the benefits of additive versus conventional/subtractive manufacturing of molds and mold components.